Contents

FemergencyThe purpose of all brake systems is to halt a moving vehicle by generating frictional force between the shoe and the wheel drum or disc. There are various approaches to make this happen—including mechanical, hydraulic, and anti-lock brake systems (ABS)—each with different degrees of efficiency.

Shop now for brakes and brake partsThe components needed to keep your braking system in top condition depend on your vehicle’s specific brake setup. Lets take a look at the different types of brake systems and how they all fit together.

Anti-Lock Brakes

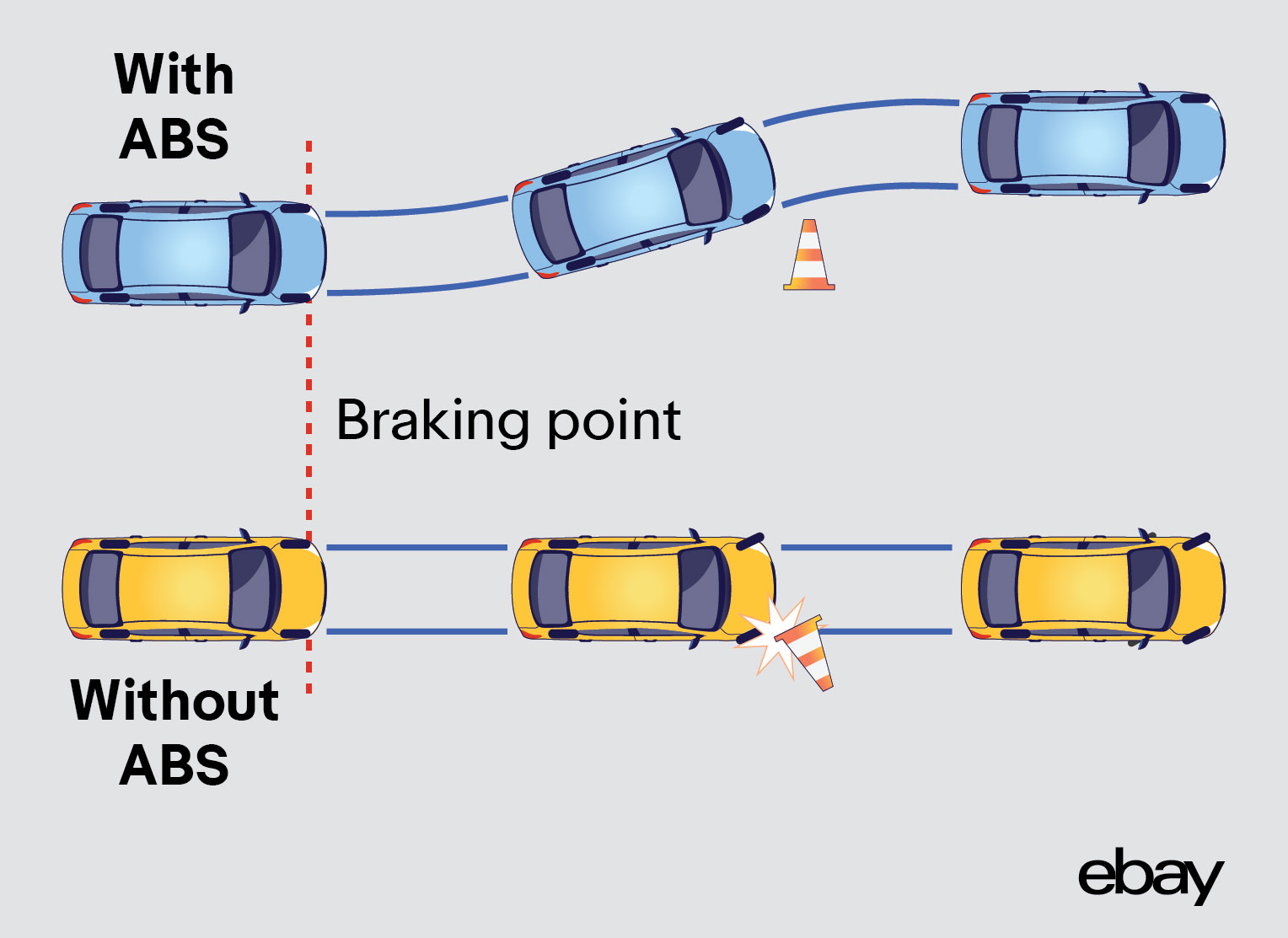

If you’ve ever slammed on your brakes to avoid a collision, you may have felt rapid pulses on the brake pedal. This is your vehicle’s anti-lock braking system (ABS) in action. ABS has been available on cars since the 1970s and became common in the 1990s. It was mandated by the NHTSA in 2012.

ABS offers several advantages. It helps avoid frontal collisions and reduces the chance of severe lateral sliding. ABS applies a lot of braking pressure while preventing the brakes from locking up. It also makes the vehicle easier to control during a panic stop.

Shop now for ABS control modulesEven light braking can trigger the ABS if traveling on gravel, icy or snowy roads. The ability to stop and steer makes ABS valuable in winter or icy driving conditions.

Automatic Emergency Braking

Automatic emergency braking (AEB) is standard equipment on most new cars. The system works with a vehicle’s existing brakes and the radar-based cruise control system.

When sensors or cameras detect an object, they determine if your car is approaching another vehicle too fast and whether you, as the driver, are taking any action to slow down in time to avoid a collision. Then, if necessary, AEB automatically activates the brakes.

Some automatic braking systems work only at lower speeds, helping to prevent fender benders in traffic. Others work at higher speeds, slowing a vehicle before an impact to reduce injuries and prevent fatalities. Some systems react to pedestrians, cyclists, and animals. Automatic braking is sometimes available when reversing.

Brake Assist

While not a brake system per se, brake assist is innovative braking technology used in newer vehicles with ABS.

During a panic braking event, brake assist automatically boosts braking pressure. Since drivers tend to panic in an emergency, they don’t always step on the brake pedal hard enough to slow down. Brake assist detects when this happens. Brake assist applies more pressure if the pedal is pressed fast and hard but without enough force.

ABS and brake assist work together to make braking more effective. This combination provides emergency braking assistance while preventing your wheels from locking.

Brake Servo

A brake servo is also known as a brake booster. Standard braking works like this:

- When you press the brake pedal, a pushrod is forced into the sealed master cylinder.

- Pistons push the oil down the brake lines to the calipers.

- The calipers are actuated, moving the brake pads against the disc and stopping the vehicle.

The most common type is a vacuum brake servo, which works on a diaphragm system:

- When the pedal is pressed, air floods one side of the servo body.

- A vacuum remains on the side connected to the air intake or hydraulic pump, creating pressure between the two chambers.

- The pressure pulls the diaphragm towards the master cylinder, forcing the pushrod into it with the help of a spring.

Without a brake booster or servo, you’re relying on the strength of your right foot alone. If your vehicle has a servo and you notice that you must apply more pressure to get your brakes working, it could be a sign that your servo needs attention.

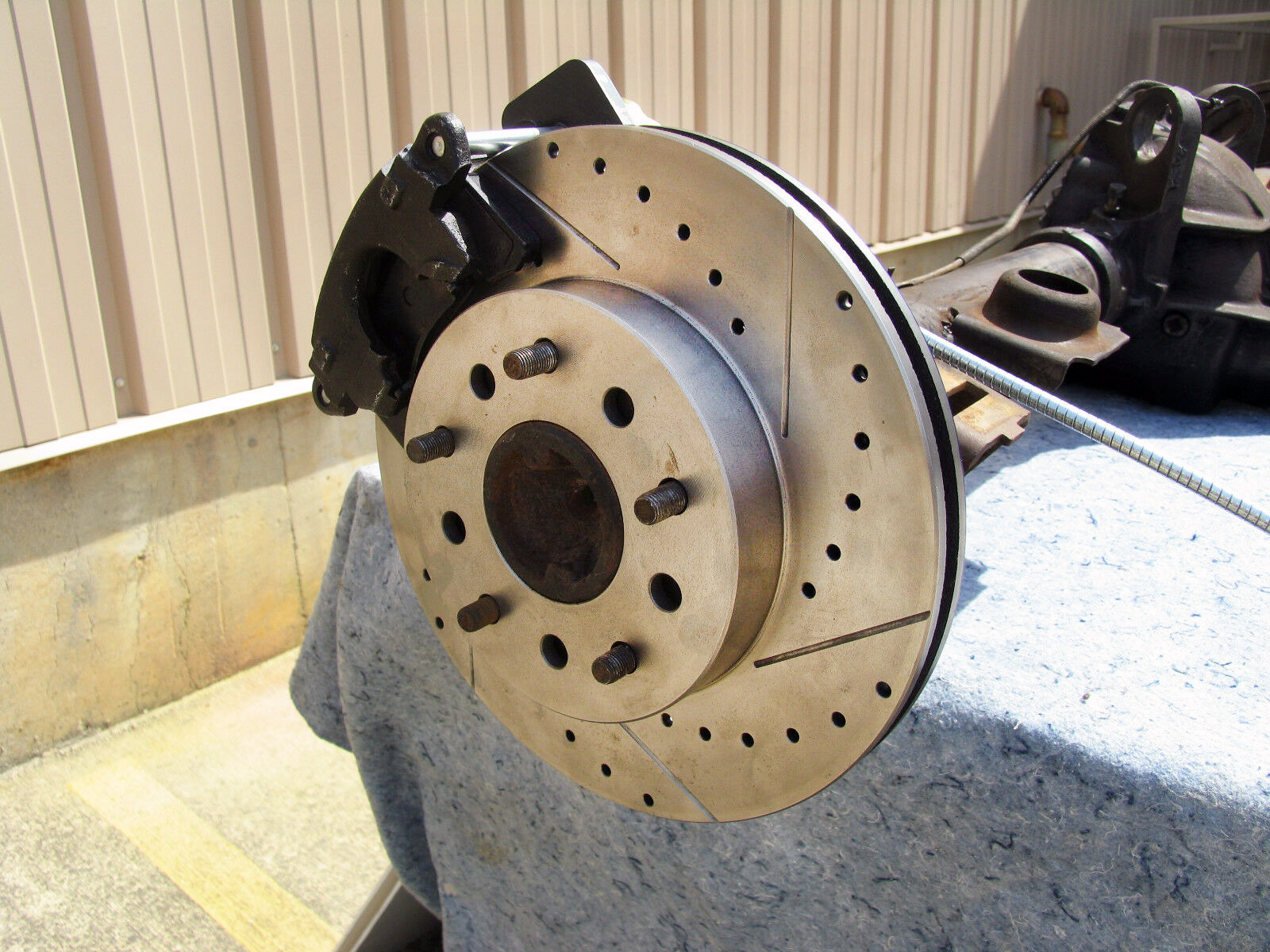

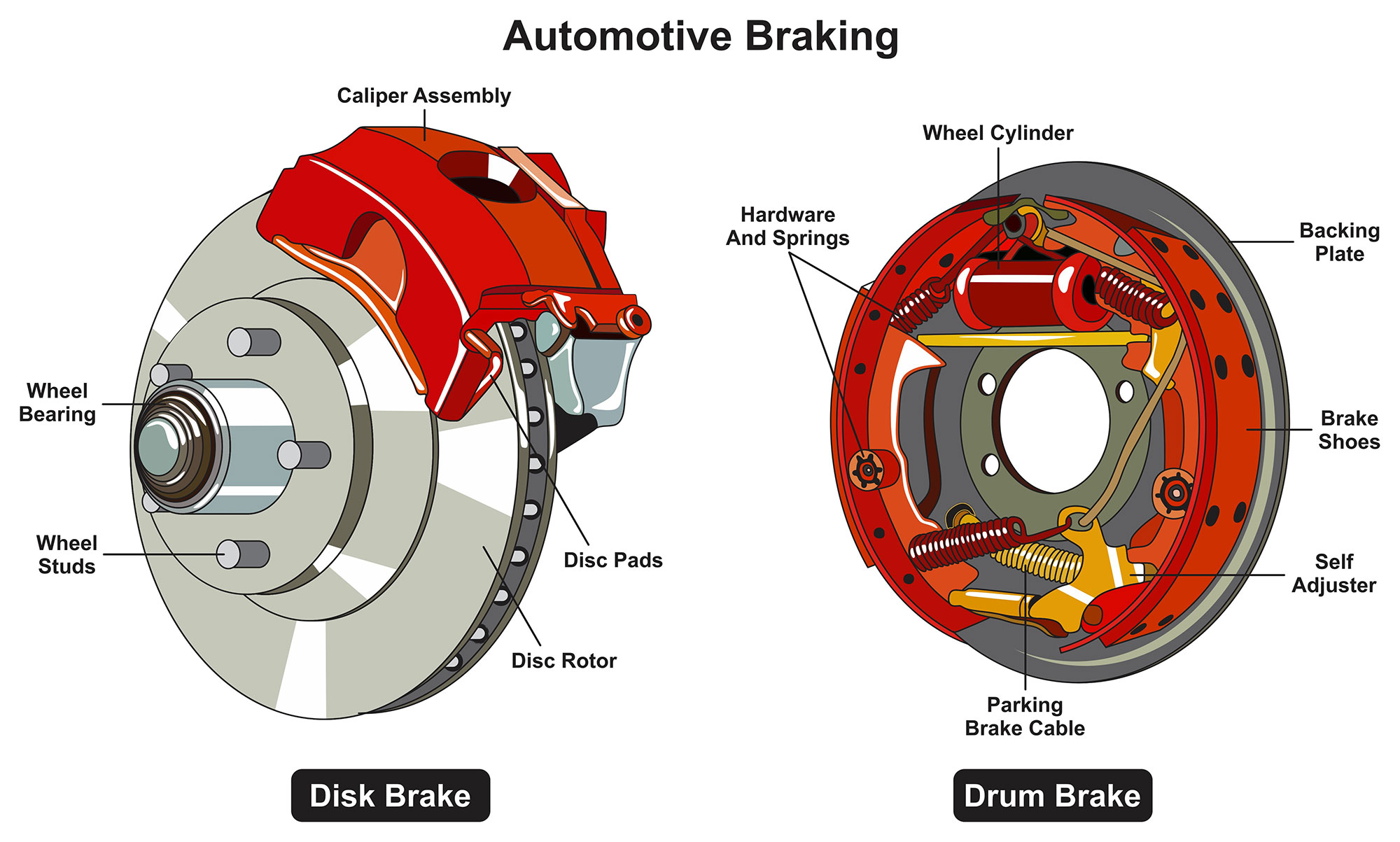

Disc Brakes

A disc brake is a mechanism linked to the wheel or axle to slow down or stop a wheel’s rotation. A disc brake is usually made of cast iron but can also be made of carbon-carbon or ceramic-matrix composites.

Disc brakes have three main parts: pads, rotors, and calipers. Each serves a different purpose. Knowing the function of each component can help you troubleshoot any problems.

Brake pads are the outermost part of the braking system. They contact and apply friction to the brake rotors. They come in the following varieties:

- Semi-metallic. Often called “semi-mets,” these pads contain metal fibers that create rotor friction. Semi-metallic brake pads are ideal for towing and heavy-duty performance. Semi-mets tend to be noisy and produce brake dust. Due to their aggressive nature, rotors generally wear faster.

- Ceramic. Ceramic brake pads are durable and provide significant stopping power. Ceramics use adhesion for stopping power, leaving a layer of sticky transfer on the rotors.

Rotors are the key to your braking system. When performing brake repair, you should always examine your rotors for wear. At a minimum, rotors should be machined or “turned” to be smooth and even. Warped rotors cause a pulsing sensation when applying your brake. Therefore, we recommend replacing rotors when you change your brake pads instead of simply machining them.

Calipers have a longer lifespan than any other part of the braking system. Calipers can last three to four times longer than brake pads. So if your caliper is failing, you should diagnose the issue as early as possible—before it puts you in harm’s way.

Shop now for disc brakesOne indication that a caliper needs replacing is a leak. For example, if the brake fluid is visible near the brake line fitting, you’ll need to replace the torn piston seal that caused the leak.

Drum Brakes

Drum brakes are uncommon in new cars. Occasionally, a vehicle may have disc brakes on the front wheels and drum brakes on the rear.

A brake drum is a hollow, cylindrical, cast iron container attached to inside the vehicle’s wheels. The brake drum constantly rotates with the wheel and never moves independently. The brake drum contains these essential components.

Shop now for drum brakes- Two brake shoes extend to push against the inside of the drum and slow your car down. Brake shoes function like brake pads.

- When you step on the brakes, wheel cylinders push the shoes toward the wall of the rotating brake drum and create enough friction to slow your car to a stop.

Emergency Brake

An emergency brake, commonly called a parking brake or hand brake, is a specialized independent braking system to use in an emergency or as a parking brake to prevent a vehicle from rolling when stopped and turned off.

The emergency brake sits to the left of the shifter in this immaculate 1965 Jaguar E-type.

The setup of an emergency brake is simple.

- A cable connects to the braking mechanism on the rear wheels.

- It is attached to a lever near the driver’s seat or a switch on the console.

- On some vehicles, it’s a push pedal on the far left side of the driver’s wheel well.

- Pull the lever, engage the switch, or step on the pedal to engage the brake.

As the lever ratchets back, the cable tightens, setting the brake, and the lever cannot release until a button is pressed or a switch is deactivated, depending on the brake setup. Emergency brakes are not powered by hydraulics and are independent of the brake system used to slow and stop vehicles.

Hydraulic Brakes

Standard in many different types of vehicles, hydraulic brakes are typically more powerful and efficient than mechanical brakes—and are easier to maintain.

Hydraulic brakes use hydraulic pressure to stop a vehicle. They are commonly used on four-wheel-drive cars, large SUVs, and pickup trucks because they provide more stopping power than traditional brakes. In addition, they’re ideal for vehicles with heavy payloads.

Hydraulic braking systems use a hydraulic pump to pressurize a fluid reservoir. This fluid is then sent to the brake pads, which create friction to slow or stop the car.

The downside of hydraulic braking systems is that they can be less reliable than standard brakes. They also require more maintenance, so keeping them in good condition is essential.

Regenerative Braking

All electric vehicles and hybrids use regenerative braking. The energy generated from braking helps charge batteries. Thanks to regen braking, brake pads can last three to four times longer than traditional braking. That’s because regenerative braking does most of the work in stop-and-go traffic.

Engineers who design electrified vehicles use software to program the intensity of regenerative braking. When this type of braking is aggressive, it can feel like the car stops itself as soon as you lift your foot off the accelerator. It’s sometimes called “one-pedal driving” because you seldom need the brake pedal.

Can regenerative braking completely recharge your EV? Unfortunately, no, but it can increase efficiency and provide extra driving range by reclaiming energy that would otherwise be lost with friction brakes.

Shop now for brakes and brake parts