Contents

What Is an Engine Leak Down Test?

As the pistons come up during the compression stroke, the air in the chamber is squeezed. If the air/fuel mixture in the chamber is not adequately pressurized, the fuel burn is more like a puff than an explosion.

A leak down tester kit comes with a gauge set and several adapters for the most common engines. You may need additional pieces for some engines.

If an engine is not running well, you can do a leak down test to determine both compression pressure (measured in psi) and the leak down rate. Compression testing alone doesn’t always show the whole story, but leak down will show you how much compression each cylinder has and how well the cylinder is sealing. If the pressure bleeds off too quickly, that reveals a sealing issue that will affect performance.

Engine leak down testing is a static test where each cylinder is pressurized individually. In comparison, for a standard compression test, the engine is cranked to determine the natural pressure level of each cylinder.

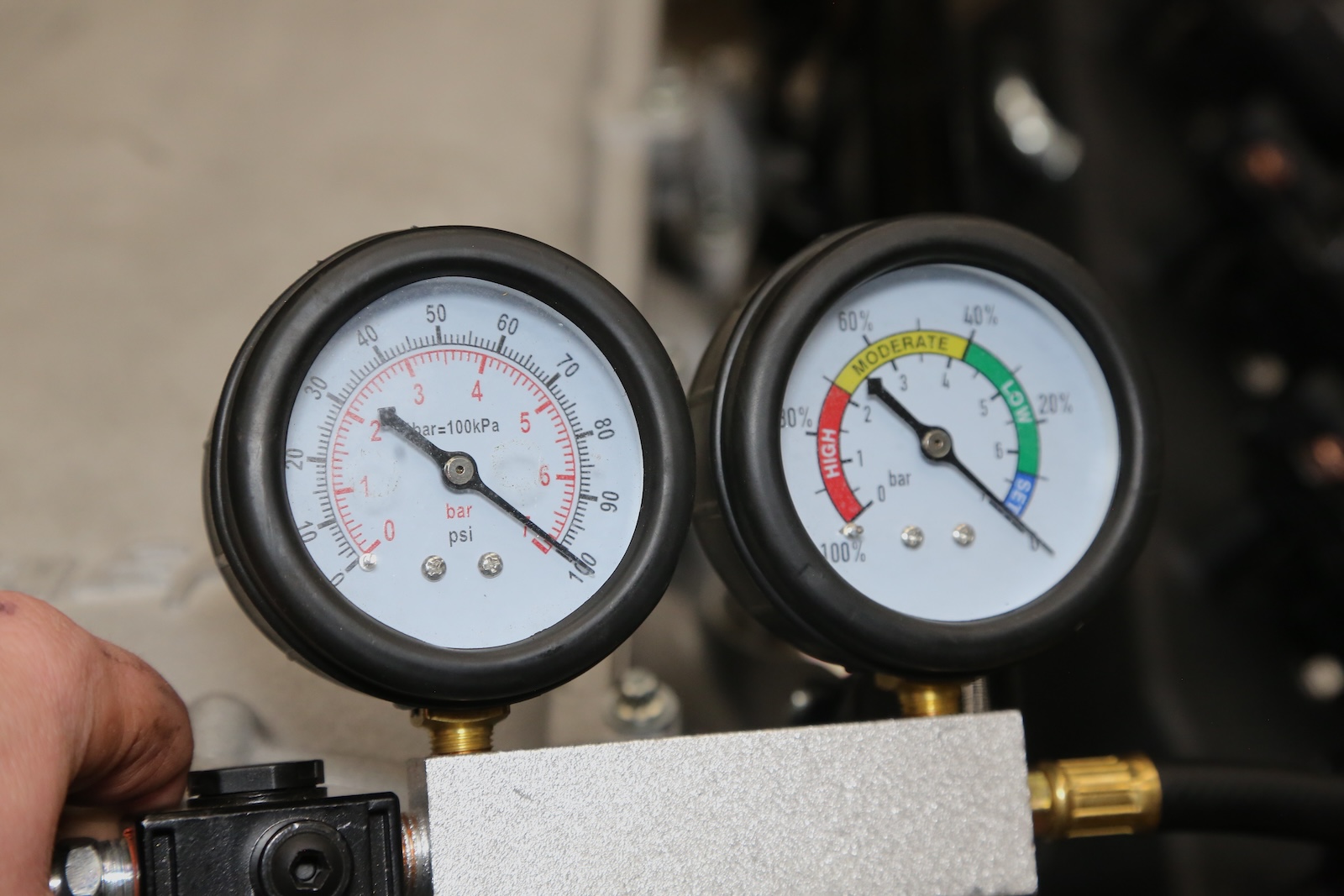

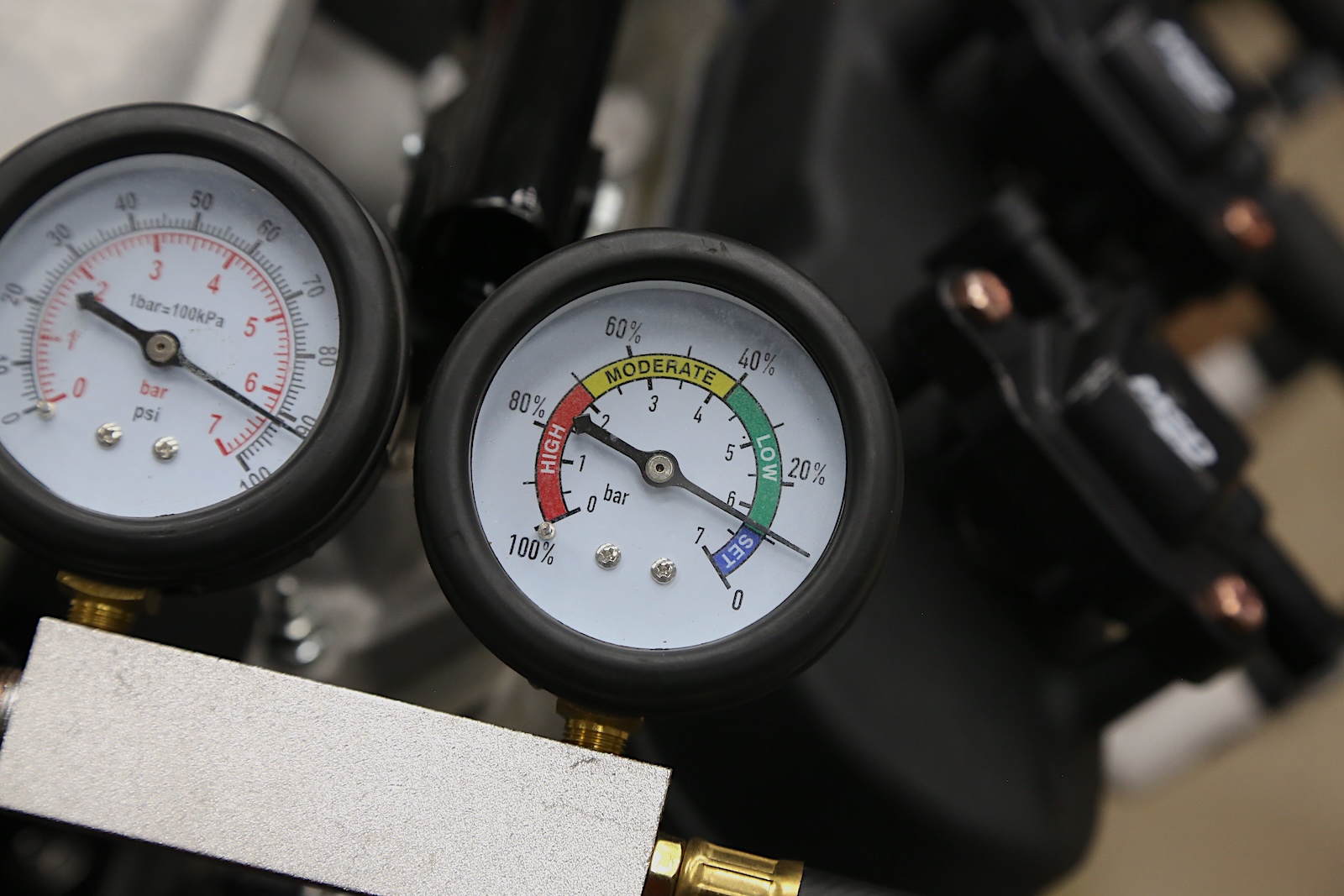

The left gauge shows the air pressure from the compressor, the right gauge shows the leak down percentage.

Anything below 20 is good, above 30 is concerning and shows potential mechanical issues.

Leak down is represented in percentages. Eight to 12 percent of leakage is typical for most engines, with a four to five percent variance between cylinders. If you get into the 20s, percentage-wise, your engine may need a ring job. Get into the 30s, and you know your engine has significant issues.

Signs and Symptoms of Cylinder Issues

You’ll want to look for these common signs of cylinder seal problems:

- Engine running poorly

- Engine overheating

- White or blue smoke coming out of the exhaust

- Check engine light illuminating

- Getting terrible fuel economy

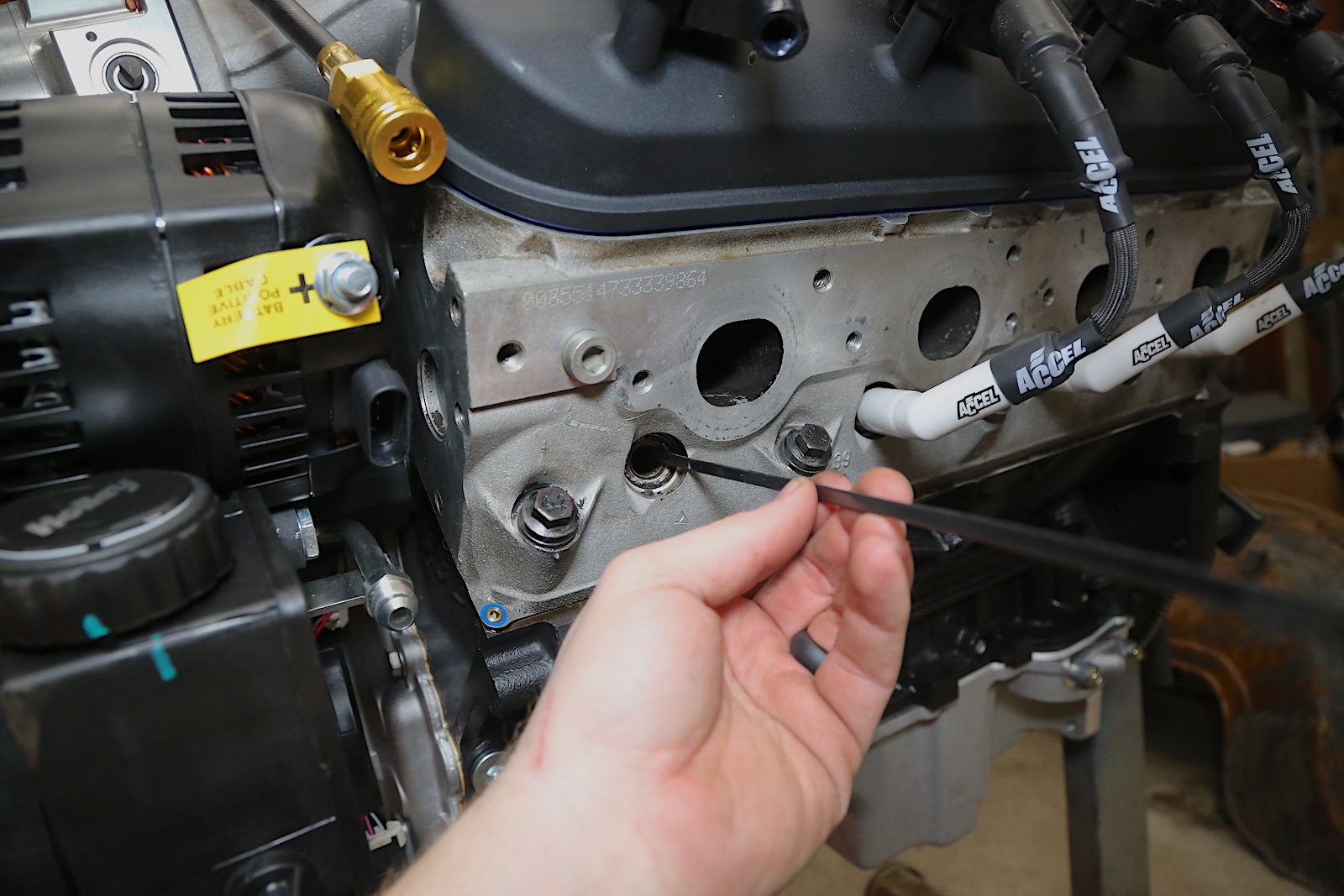

First, the number one spark plug was removed. You can start anywhere, but if you are doing this test, you might as well start at the number one and go through the entire engine.

Note that these are the same as blown head gasket signs.

Gather Your Tools

You need an engine leak down testing kit to test the cylinder’s seal, which ranges from $25 to $200. This can be a single-gauge or dual-gauge tool. The dual-gauge tools are easier to read and more common. The gauges can be analog or digital. You want to select a kit with multiple adapters for various spark plug types and depths of installation. Some vehicles have deep ports for the spark plugs.

Using a zip tie, piston stop, or small screwdriver is an easy way to ensure the cylinder is at top dead center. Just don’t let the tool get pinched, which can damage the engine.

Here’s what you’ll need to have handy during the test:

- Leak down test kit

- Socket set (for spark plugs)

- TDC stop, zip tie, or screwdriver

- Air compressor

- Breaker bar with crank bolt socket

- Soft mallet

How to Perform an Engine Leak Down Test

Testing leak down is a bit of a chore, especially if the engine is in the vehicle. The engine needs to be warm, so start it, let it come up to temperature, then allow it to cool for 20 minutes. It should retain heat sufficient to ensure the rings seal while allowing the exhaust to cool down enough to work around without too much risk of burns. Wear hand and arm protection when working around a hot engine.

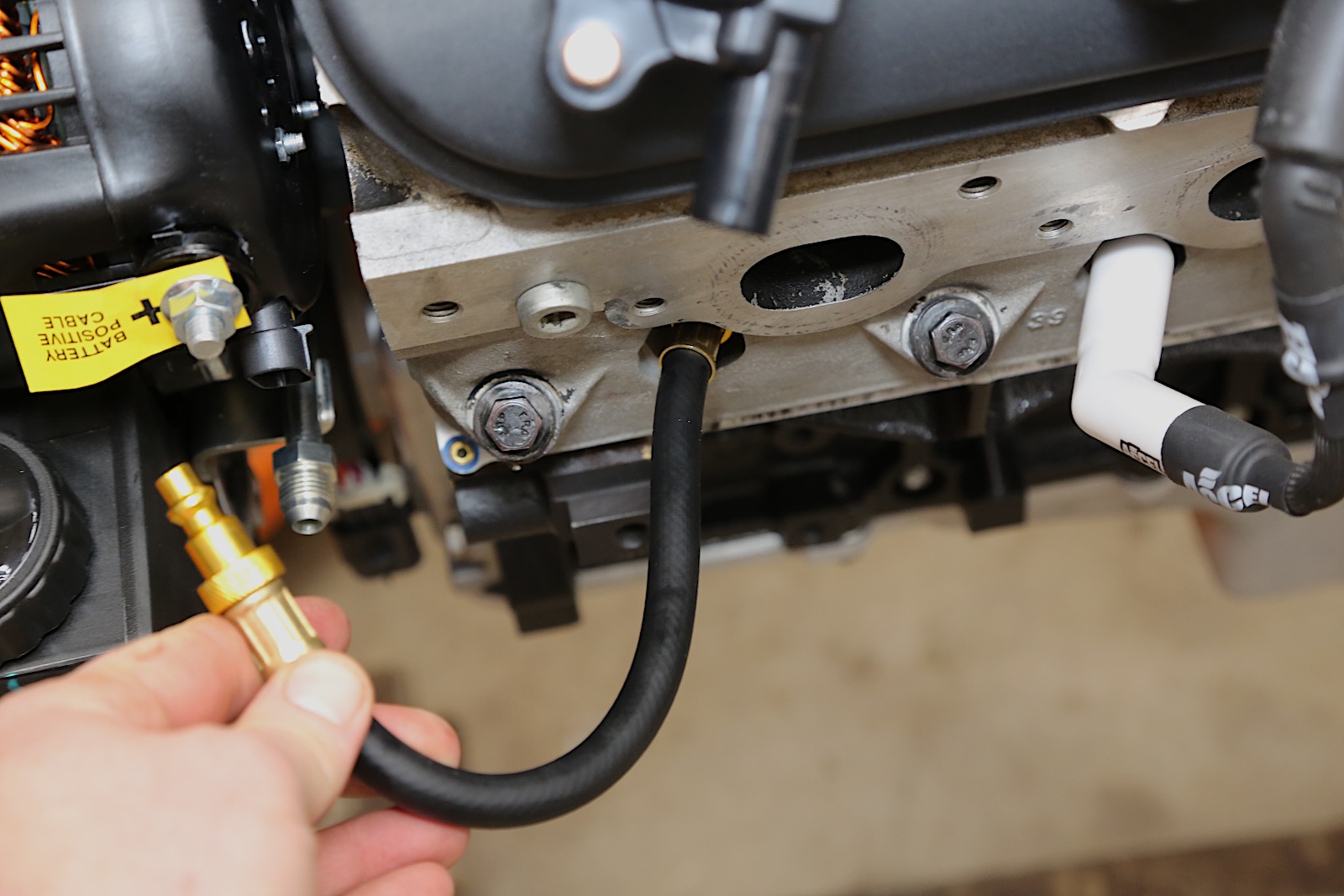

Next, the adapter is threaded into the cylinder head.

Remove the number one spark plug. Since this process requires testing every cylinder in the same fashion, start on number one to keep things simple. Wait to remove the other plugs.

- Rotate the engine by hand until the number one cylinder is at the top dead center (TDC). You can use a TDC stop that threads into the spark plug hole, a zip tie, or even a small screwdriver inserted into the chamber to feel the piston rise and then stop. Be careful with metal objects—you don’t want to put the piston in a bind and break it.

- Install the testing hose into the spark plug hole using one of the supplied adapters.

- Connect the air compressor hose to the tool to pressurize the chamber. Tools have an adjustable valve to let pressure in. 45 to 150 psi is the typical range, and 100 to 120 psi is suitable for most engines.

- Note the total pressure and the leak down rate. If it is below 15 percent, there is likely no issue in that cylinder. If it is higher, then continue with the next steps.

- Rock the crank back and forth a few degrees each way using a breaker bar. This will help seal the rings in the cylinder. If the leak down rate decreases to a livable level, then you are good. If it increases, there is likely excessive ring wear.

- Remove the air intake tube, radiator cap, and oil dipstick. You are looking for the leak path in the intake, exhaust, water, or oil system.

- Put your ear close to each opening while pressurizing the cylinder. For exhaust, simply walk back to the exhaust tip and listen.

You have to set the gauges before connecting them to the engine port. Simply connect to the air hose and open the regulator until the right gauge is maxed at the “set” position.

Intake – If you hear air from the intake, then you either have an intake valve seal issue or the engine is not at TDC. Anything over 18 to 20 percent indicates a leaky valve seal. Remove the valve cover and tap the valve stem with a soft mallet to reseat the valve, which could complete the seal. The same trick works for the exhaust valve. One cylinder leaking at 20 percent when the others are under 15 percent is not likely to be worth the trouble to repair, but if more than one is above 20 percent after tapping, a valve job is likely in order.

Exhaust – If the exhaust leaks air, the issue is in the exhaust valve. For most engines, your leak down needs to be above 30 percent before you need to get concerned about exhaust valve leakage.

Water – You may hear gurgling or see bubbles in the radiator or overflow tank, indicating a blown head gasket into a water jacket. Rebuild time!

Oil – Gurgling or air hissing from the dipstick tube means the issue is in the piston rings. Rocking the crank back and forth a few degrees helps seat the rings and lower the leak. If the rate of leak down is between 15% and 20% on all cylinders, then the engine has some ring wear. You could rebuild it, but it isn’t worth it at 15 or 20 percent. Once you get into the 30s and the rings leak, you should consider a ring job on the engine.

Repeat these steps with each cylinder. Don’t forget to bring each piston to TDC before testing.

Then connect the test hose to the gauge set and the right gauge shows your leak down value. This cylinder is showing 11%, which is about perfect.

Testing your engine’s leak down rate is an easy way to find problems. Keep in mind that no engine is completely sealed. Once broken in, nearly all engines have a four to 15 percent leak down rate. Engines that are boosted with a turbo- or supercharger will have higher leak down rates because the rings have a larger gap, so they just don’t hold pressure as well. This is normal and should be considered when doing your tests.

Shop now for engine leak down test kits