Contents

While that sounds simple, driveshaft science is quite complex.

- It spins at very high rpm.

- When you are in overdrive, it spins faster than the engine itself.

- When you’re on the highway doing 80 mph, and the engine is turning 3,000 rpm, your driveshaft could be spinning at 5,000 rpm, depending on the overdrive gearing.

This rotational force must be contained. Otherwise, the driveshaft can bend at speed, which is called “jump roping.”

An adequately designed driveshaft can yield more speed. On the other hand, any little wobble, warp, or vibration kills power.

What Is a Driveshaft?

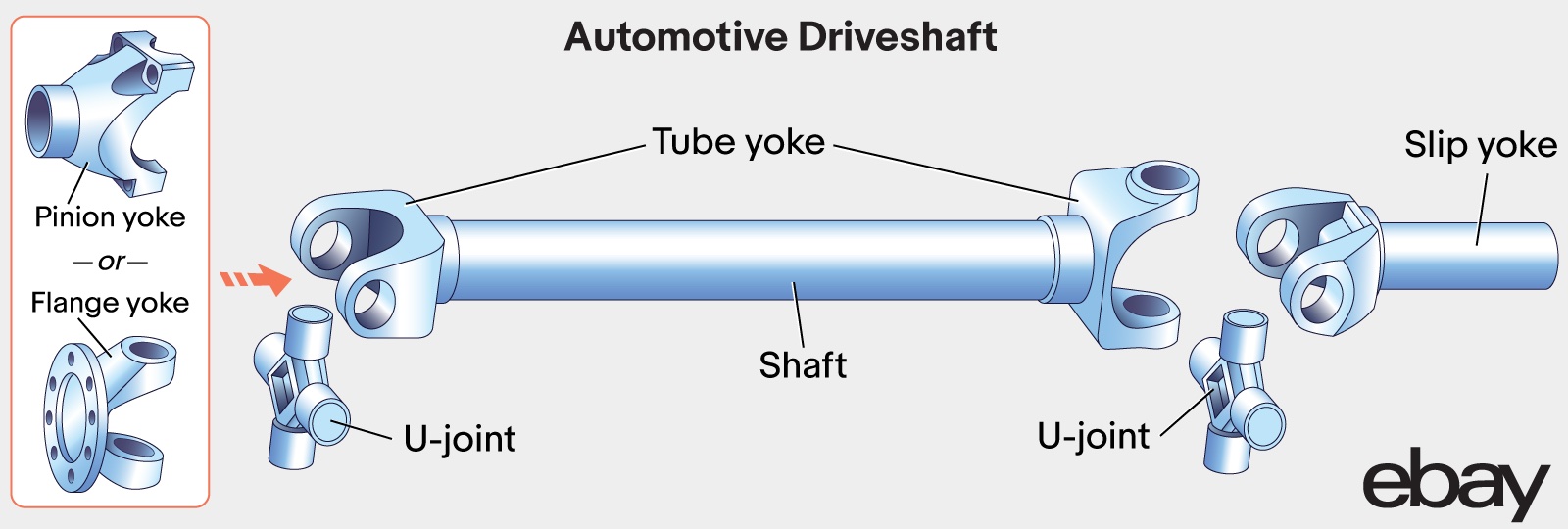

Common driveshaft components include interlinked yokes and joints. Rear pinion yokes are common, but some vehicles use a flange yoke to secure the driveshaft to the rear axle instead.

There are several components to a driveshaft:

Slip yoke – This part slides in and out of the transmission as needed to accommodate suspension travel. It’s specific to the transmission.

Pinion yoke – At the axle, the pinion yoke bolts to the pinion gear shaft, which connects the ring gear. The pinion yoke is sometimes a part of the driveshaft, where it bolts to a flat flange on the pinion. But in most cases, the pinion yoke bolts to the pinion gear, and the pinion U-joint bolts to the pinion yoke.

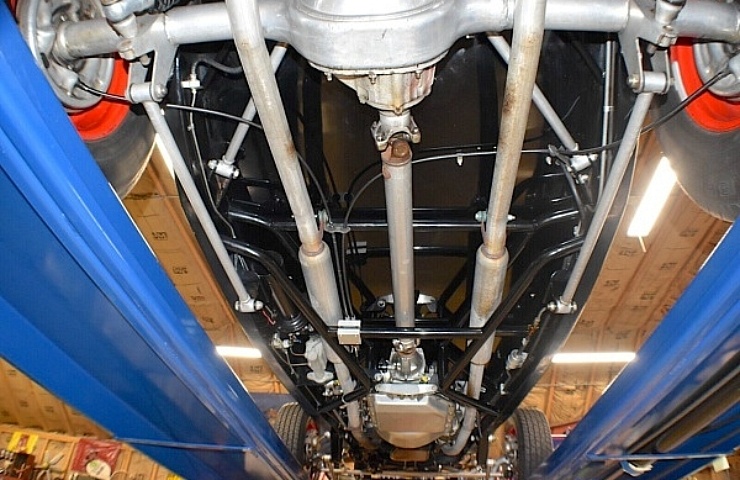

Carrier bearing – Most cars do not use these, but some do, as well as a lot of trucks and SUVs. When the driveshaft has to be longer than can safely be supported by a single-piece driveshaft, the shaft is made in two or sometimes three sections supported by a carrier bearing, which bolts to the chassis. This is a pillow block bearing with splines so that there is a slip feature for suspension movement.

Universal joint – Often called U-joints, these are the workhorses of a driveshaft. There is a U-joint at each end of the shaft, which connects the yokes. The U-joint works like a fuse in that the joint will break before the driveshaft twists. U-joint care is essential to the life of the driveshaft—and you and your passengers.

Shaft – The shaft is critical for proper vehicle design. If you put more power in front of a stock driveshaft, it likely won’t handle the power. It can twist or break, leaving you in a bad spot. Don’t rely on a small driveline shop for high-horsepower driveshafts. It would be best to have a specialist dealing with proper design. Ask questions about how the shop designs and builds its driveshafts to ensure they can make a high-performance unit.

Shop now for driveshaftsDriveshaft Balance

Your original driveshaft will likely last the lifetime of the vehicle. Things do happen—a U-joint might break, the driveshaft might get dented, or a balancing weight might fall off. If your driveshaft is damaged or goes out of balance, you must fix it.

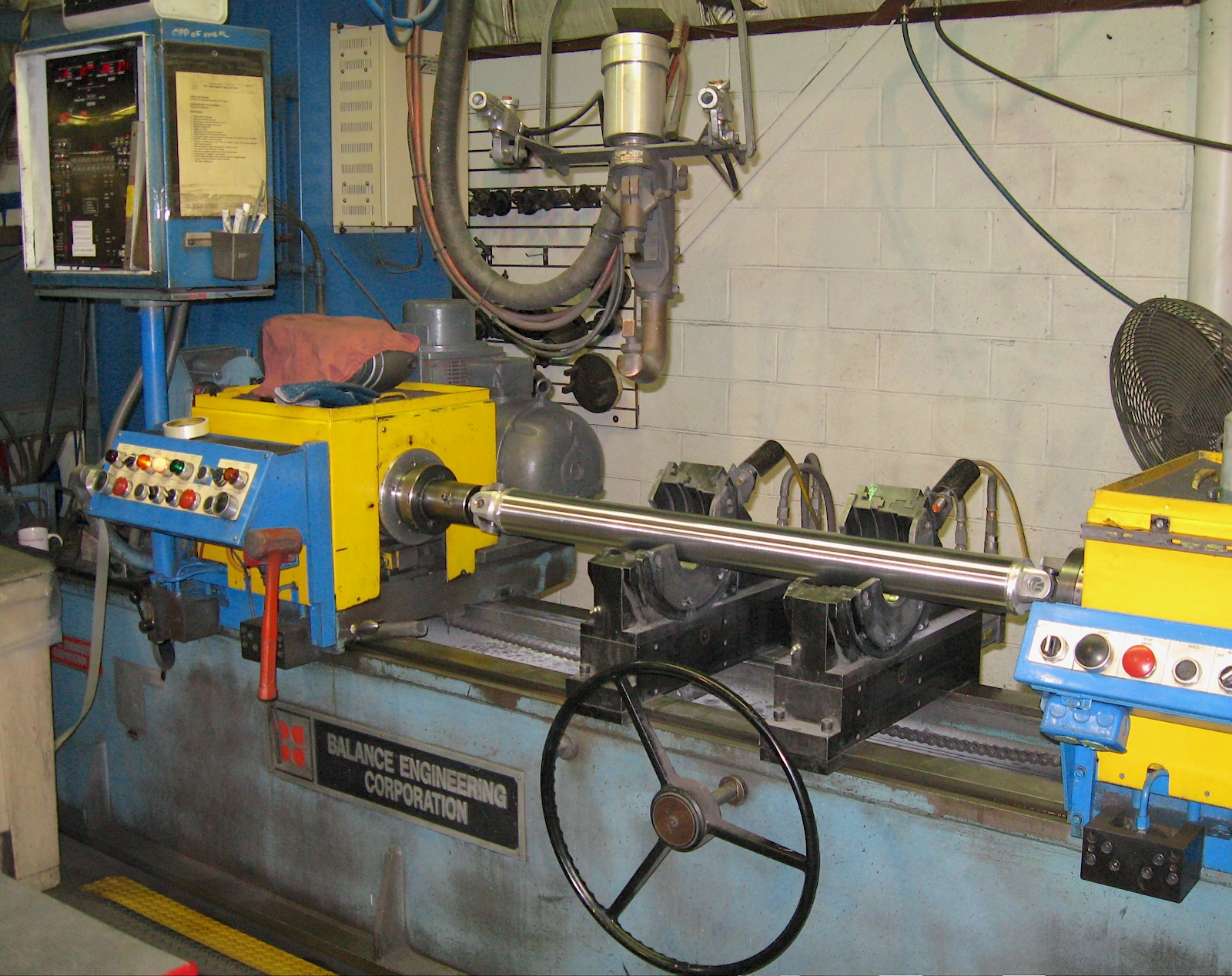

This driveshaft balancing machine is the right way to do the job. There is no good way to balance a driveshaft at home. The “old school” tricks simply do not work.

The biggest issue with a driveshaft, besides problems with the U-joints, is the balance. The driveshaft must be perfectly balanced end to end. Otherwise, you get vibrations in the vehicle. The balance weights (like wheel weights but welded to the shaft) can occasionally break off the shaft. If that happens, you will notice a vibration at certain speeds. It may come and go at different speeds, or it may be constant.

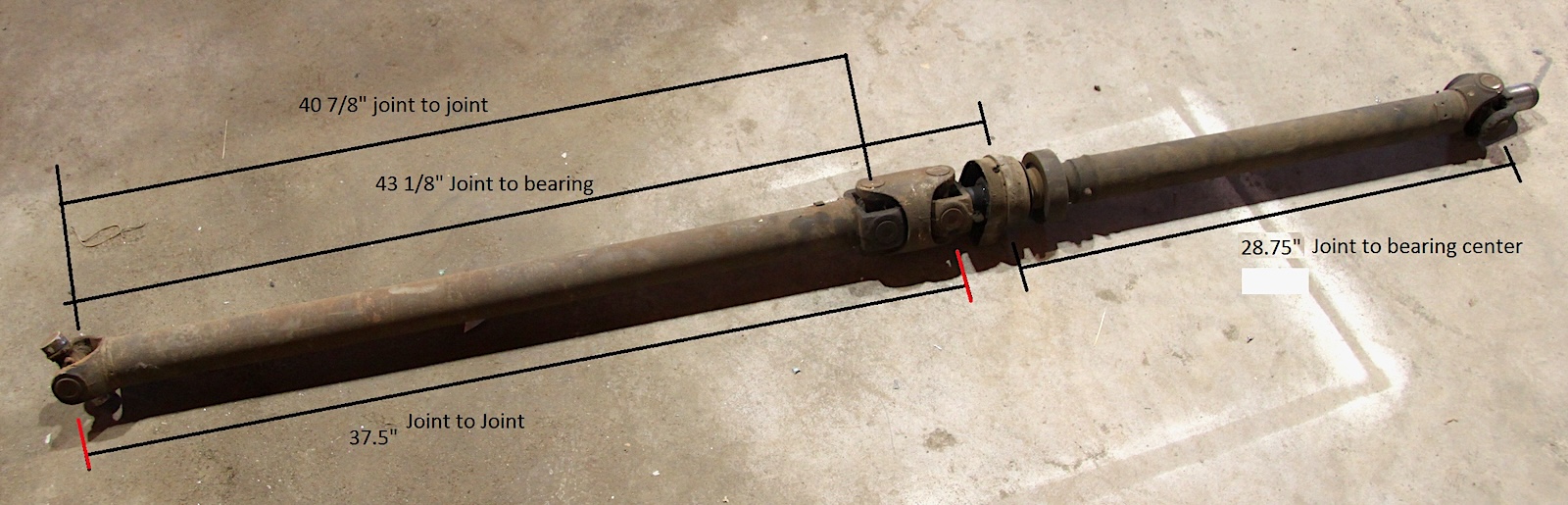

Measuring a driveshaft can seem intimidating because if you get it wrong, you end up with a shaft that doesn’t fit. This is a two-piece shaft with measurements added to show you how to measure an existing shaft.

Balancing a driveshaft requires a special machine that spins the shaft up to 3,300 rpm and then measures the balance. Once the balance point is found, a weight is welded onto the shaft at one end to fix the imbalance.

This must be done as a complete unit, from the slip yoke to the pinion yoke or pinion U-joint. During the work to balance the driveshaft, the technician should inspect the shaft for defects that can affect its condition.

Most shops only balance shafts at speeds between 3,000 and 3,500 rpm. For high-performance applications, this needs to be done between 5,000 and 7,500 rpm to take higher speeds into account.

Measuring a Driveshaft

If you need a new shaft, measure the tailshaft of the transmission at the end of the housing itself (the seal is a great measuring point), not the output shaft.

When you need a new driveshaft, you only want to pay for it once, so getting the measurements right is critical. The biggest mistake people make when ordering a shaft is making it too short.

The key is to measure the length under the vehicle with the weight on the suspension, not suspended on jacks. If you need to raise the car, use jack stands to support the suspension so that the vehicle’s weight is on the suspension.

At the rear pinion yoke, measure to the flat surface of the end caps/strap bolts. This is the center of the rear U-joint.

- Enlist a helper to measure.

- Place one end of a tape measure on the pinion yoke flange where the U-joint U-bolts go. This is the center of the U-joint cap.

- Run the other end of the tape measure to the transmission seal flange. Make a note of its length.

- With this one measurement, a competent driveshaft shop can build your new driveshaft (if you keep the yokes the same).

If you are ordering a new driveshaft for a custom build, you also need the measurements for the pinion yoke—both width and diameter and the same for the slip yoke.

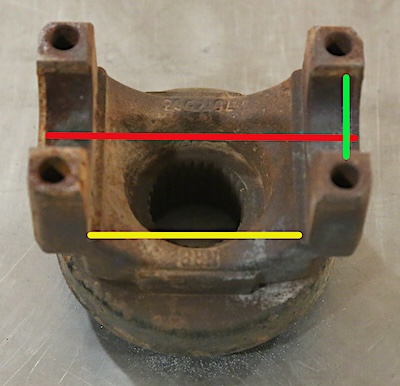

You also need the rear pinion yoke measurements. The red line is the width of the saddle where the bearing caps sit, if there is a notch on the outside, measure between them. If there are no notches, measure between the saddles (yellow line). The green line is the width of the U-joint saddle.

Ensure that the shop provides only a little runout. The runout is the amount of slip yoke that hangs out of the transmission. The correct length is one inch, but can be as much as 1.5 inches. Any more than that, and you’ll have vibration and transmission seal wear.

When you upgrade your engine to make more power, the driveshaft is often forgotten—until it explodes spectacularly. A stock shaft is usually good for 100 to 150 more horsepower than stock. If you add more than that, you’ll likely need to buy a custom shaft designed for your application.

Shop now for driveshafts