Contents

What Is a Spark Plug Gap?

A spark plug receives a high-voltage signal from the coil to the plug tip. The signal goes through the plug via the center core to an exposed center electrode on the end of the plug inside the cylinder head. The signal needs to find a ground to complete the circuit.

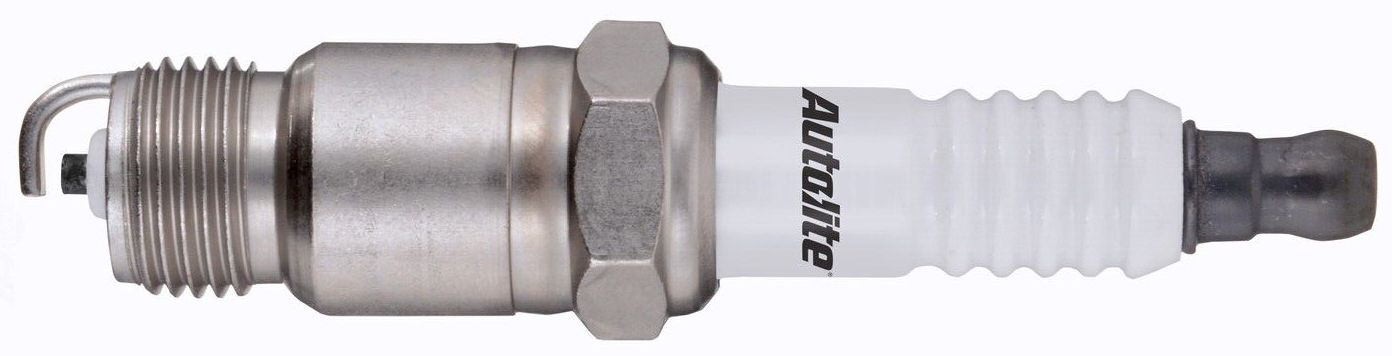

The little hook that hangs over the end of the spark plug is called the ground electrode. The gap is the distance between these two electrodes.

The little hook (on the left) that hangs over the end of the spark plug is the ground electrode.

When the spark occurs, a small amount of fuel is ignited, and the result is called a flame kernel. The flame kernel ignites the rest of the fuel in the combustion chamber. The gap is critical to the propagation of the flame kernel.

- If the gap is too small, the flame kernel of the spark is too small to ignite the entire combustion charge.

- If it’s too large, the spark may not jump the gap at all, leaving you with a no-spark miss.

The Proper Spark Plug Gap

Spark plug for 1956-1968 Corvette

Out of the box, most spark plugs have a base gap for the most common application for that specific plug. But the same plug fits hundreds of different engines, and that factory-set gap may not be suitable for your application.

Some old-school basic standards exist:

- A stock street engine is .025 inches

- A performance engine is .028 inches

These are just the starting points—every manufacturer has different plug gaps. Even these standards are only for older engines with points-type distributors. As ignition systems improved, the plug gaps got bigger—more spark energy equals a bigger plug gap. A gap of .044 inches is much more common now.

The point is that you need to check your plug gap every single time you install a spark plug, as you may get one plug that is .044 inches, one that is .063 inches, and one that is .025 inches. If you installed each of these, your engine would have differential combustion events, leaving you with a rough-running engine and poor efficiency.

How to Gap Spark Plugs

A wire-type gapping tool is the correct gauge and adjustment tool for platinum or iridium spark plugs.

Coin-type spark plug gap tool

First, let’s talk about tools. The little coin-type keychain plug gap tool is great for the classic copper/nickel plugs with a big fat center electrode. But most newer cars spec fancy plugs that use platinum, iridium, or ruthenium. These precious metal electrodes are much thinner than the copper/nickel plugs. A coin-style tool will break the tip of a $5 or $10 plug.

The correct gauge and adjustment tool for platinum or iridium plugs is a wire-type gapping tool.

You don’t always need a set of feeler gauges, but having one on hand for this process is a good idea because the wire-type tool does not have as many gap sizes built in.

Shop now for gap toolsUsing a coin-type tool

- Determine the correct gap for your engine.

- Slip the edge of the coin gapper between the two electrodes. Slide it carefully until it stops. Read the gap on the hash marks on the coin.

- To open the gap, slip the electrodes over the keyring hole (which isn’t actually a keyring hole) and gently pry upwards.

- To close the gap, gently hold the plug in one hand and gently tap the ground electrode on a hard surface such as a bench top. Yes, this is the official method when using a coin tool.

- Recheck the gap to ensure it is correct. Do this for every spark plug.

Feeler gauge

Using a wire-type tool

- Check the gap by using the bent wires on the tool to find the one that fits tightly. Do not force the wire in. It should slide in and out easily, barely making contact on both sides.

- If the gap you need is not included in the tool, you need feeler gauges. Select the feeler gauge that matches your gap.

- If your gauges do not have the exact gap in a single gauge, you can add them together. Slip it between the electrodes.

- To open the gap, use the small hook on the end of the tool. Slip the hook over the base of the ground electrode nearest the threaded base and gently pry the ground electrode away from the center.

- To close the gap, use the same hook but gently pry the ground electrode toward the center electrode.

- Recheck the gap to ensure it is correct. Do this for every spark plug.

Checking the gap of your plugs only takes a few minutes, but can save you a lot of money in fuel costs and premature wear on your spark plugs. Even if a spark plug says it is pre-gapped, that gap may not be correct for your vehicle.

The typical change interval for spark plugs is 50,000 to 100,000 miles. Gap your plugs, save some fuel, and get better performance. Besides, it’s free horsepower.