Contents

Diagnosing a Bad Fuel Pump

First, you must know if the fuel pump is the issue. Fuel pumps do not typically provide warning signs that they are going bad. They either work or they don’t.

Once the tank is out, you can access the fuel pump itself. This tank is from a 1992 Chevy 1500 truck. Expect a lot of dirt.

If you get a warning sign, it will be a hard start, followed by stumbling, hesitating, and stalling. Watch the check engine light; if it’s illuminated, you should check the codes with an OBDII scanner. When low fuel pressure codes show up, your issue could be in the fuel filter or in the pump itself.

You might have to break up some crud to access the retainer.

You can verify if the system is getting fuel by having an assistant turn the key to the on position—not start—while you press the test port valve on the fuel rail. Not all vehicles have a test port, but most do. It looks like the air valve on a tire. Use a rag to catch any fuel that comes out. If fuel comes out at pressure, it is not the pump. When very little fuel comes out, it could be the pump, but the fuel filter is the likely culprit. If no fuel comes out, the pump or filter are both suspect.

When the pump is turning on, but you get little to no fuel, replace the fuel filter and test again.

About a half-turn is needed to release the retainer ring.

The last step is locating the fuel tank and getting as close to it as possible. Let the engine sit for at least 30 minutes to cool, then have your assistant turn the key to the on position. You should hear the fuel pump turn on for about five seconds to pressurize the system. It is likely bad if you do not hear the pump come on.

One last thing before dropping the tank and replacing the fuel pump: check the power to the pump. If the pump wiring is accessible, use a digital multimeter set to DC volts in a 20-volt range to verify that the pump is getting power. If it isn’t, check the fuse and fuel pump relay.

Then the pump slides out. You will need to roll the sending unit around to get the fuel level arm out of the tank.

How to Replace a Fuel Pump

Once you have exhausted all the other possibilities, it is time to replace the fuel pump. Here are the tools you’ll need to round up:

- Jack stands or ramps

- Small floor jack or wood

- Wrenches, screwdrivers

- Hammer and chisel

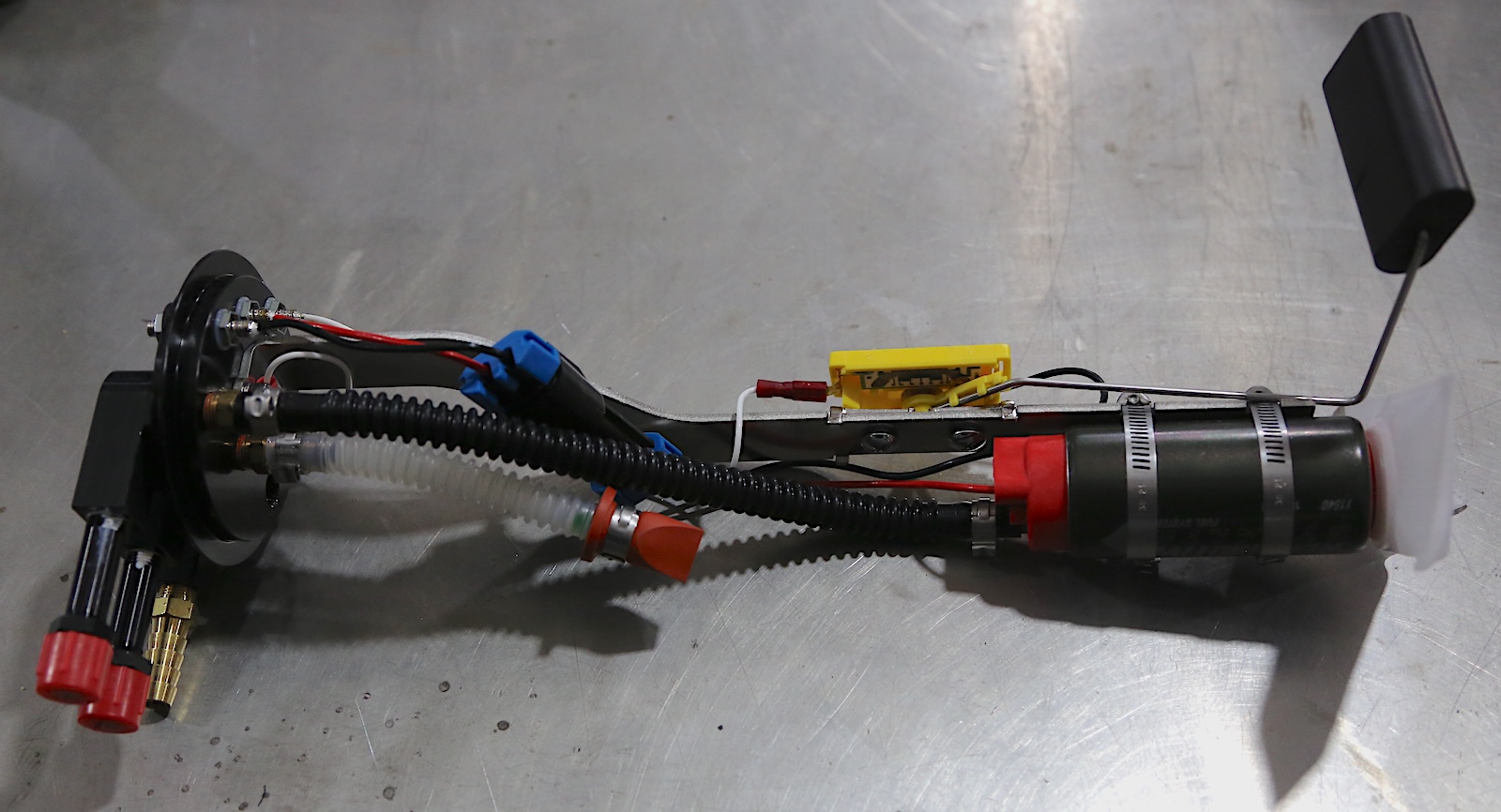

This is a new drop-in module for the Chevy truck. This is an aftermarket performance fuel pump and sending unit.

The following steps are generalized procedures for replacing a fuel pump in the most common vehicles. Your vehicle may require additional steps not included here. Check your vehicle repair manual for specific details. Also, you can simply replace the entire module with a new one in many cars, but some older vehicles require replacing just the pump.

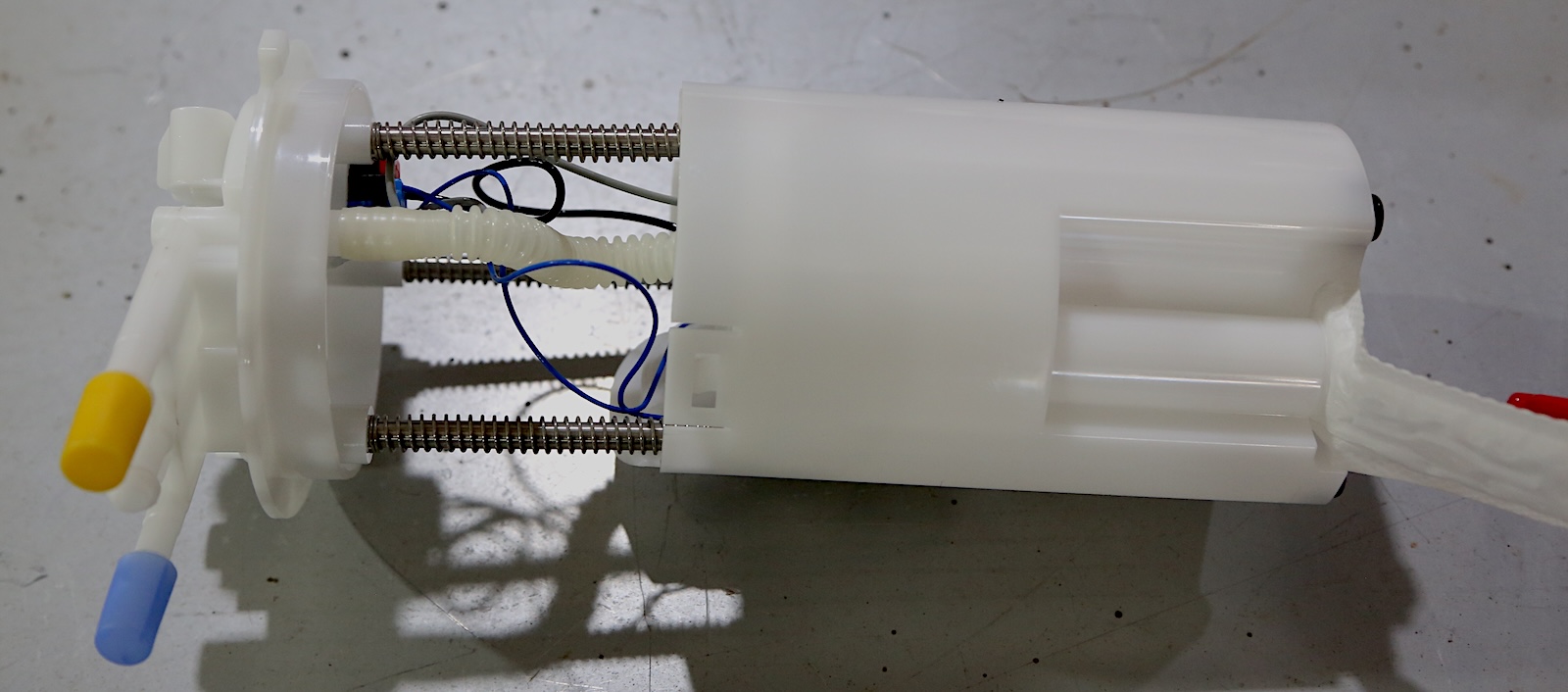

For later vehicles, your pump module may look like this one, which is for a 2015 Chevy truck.

- Locate the fuel tank and then the pump location. Some vehicles have the tank in the trunk or provide a pump access cover. Some models make it easy to replace the fuel pump, but most require dropping the tank.

- Disconnect the battery negative terminal. You do not want sparks while you are working around a fuel tank.

- Raise the vehicle safely with jack stands or drive-on ramps.

- Locate the tank mounts. Most tanks use straps, but some have bolt-in flanges. Use a small floor jack with a wide block of wood to support the bottom of the tank while removing the tank mounts.

- Remove the filler cap and any ground straps, bolts, or screws inside the filler door. You may be able to disconnect the filler hose under the vehicle, but some tanks have steel filler necks that are not removable.

- Slowly lower the jack. This should expose the pump mount, wiring, and hoses.

- Disconnect the wiring and hoses.

- Remove the tank from under the vehicle.

- Remove the fuel pump. Some bolt in, and some use a rotating ring and seal. Use a small hammer and chisel or flat-blade screwdriver to lightly tap the ring out of the mount for ring and seal mounts. This is typically counterclockwise. Most have three or four tabs, so switch back and forth to keep the ring centered while you drive it out.

- Pull the pump from the tank.

- Unplug the pump from the sending unit.

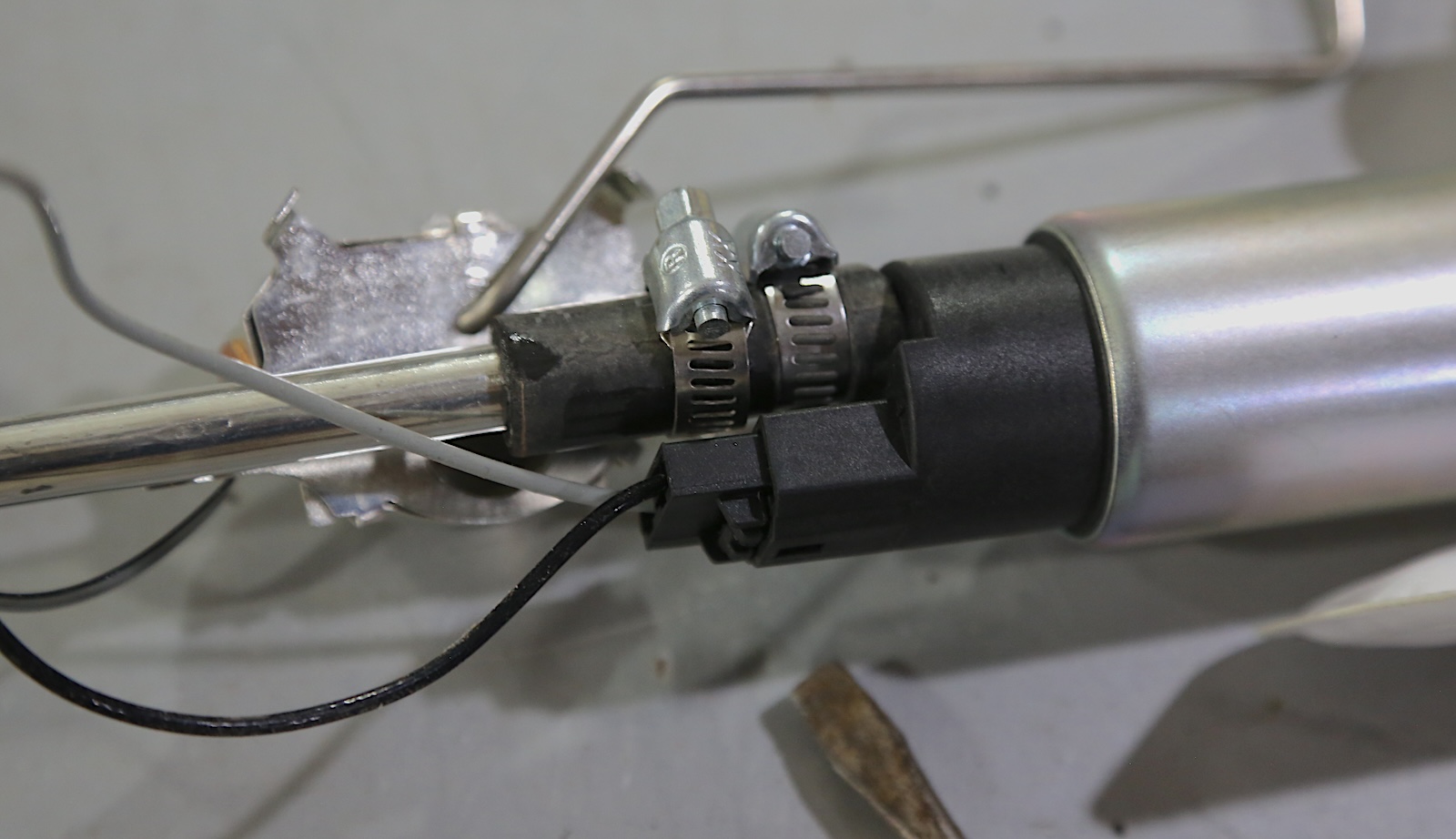

- Release the hose clamp from the pump output hose.

- Loosen the clamps holding the pump to the sending unit and remove the pump.

- Slide the new pump into the output hose and reinstall the clamps to the hose and the sending unit itself.

- Install the new filter sock to the base of the pump.

- Reinstall the pump into the tank in reverse, and then the tank into the vehicle.

Cost of a New Fuel Pump

On average, a new fuel pump costs $100 to $500. A typical pump is around $200. Labor to install a fuel pump is where it gets expensive, with a range of $300 to $600, but it can run up to $1,500 for complex installs.

If you need to retain the sending unit when replacing the fuel pump, loosen the hose clamps and pull the pump from the hose.

The key is whether or not the tank has to come out. Most vehicles require dropping the tank, but sometimes, you can access the pump from inside the trunk or under the rear seat. Trucks often require pulling the bed off, which is faster and easier than pulling the tank.

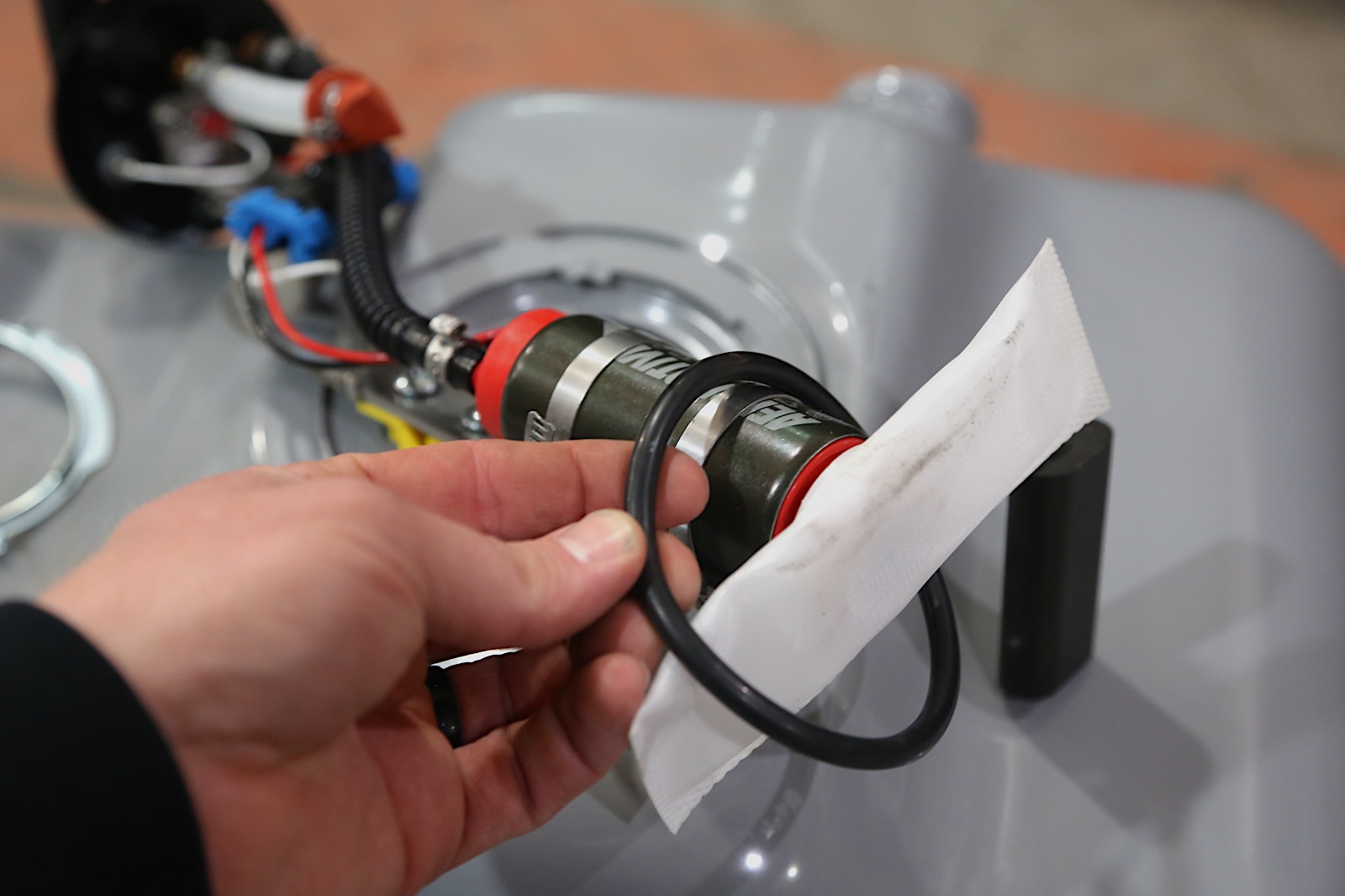

Don’t forget to install a new filter sock and O-ring before reinstalling the pump into the tank.

Replacing a fuel pump is an intermediate job for most DIYers. It will take three to five hours to complete and requires no special tools other than a small floor jack.

Finally, reinstall the retainer ring (or bolts), then reinstall the tank into the vehicle.

Pro tip: In-tank fuel pumps require fuel to keep them cool. Keep your fuel tank from going below a quarter full. This makes the pump too hot, making it harder to pull enough fuel to feed the engine. Driving with consistently low fuel levels adds a lot of wear to a fuel pump.

Shop now for fuel pumps