Contents

What Is an Engine Mount?

Motor mounts attach the engine to the vehicle to hold the engine in place. Every mount is connected to the car body on one side and to the engine on the other.

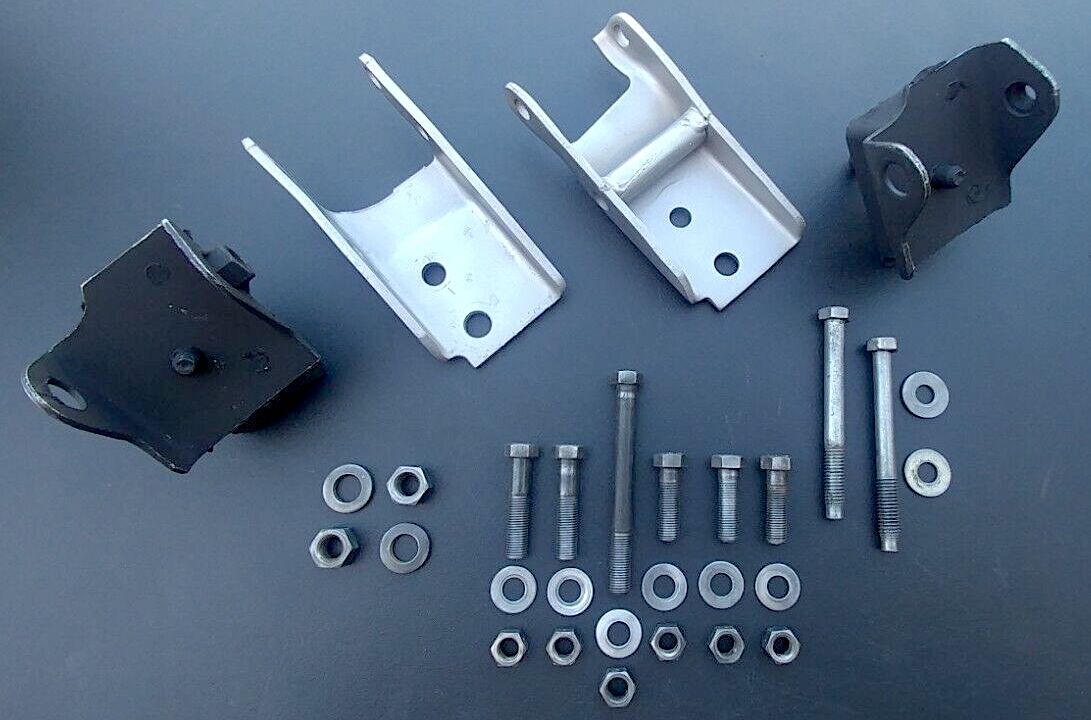

Big block V-8 Mopar engine mounts

Typically, these mounts are made from rubber to prevent metal-to-metal rubbing between the engine and vehicle. However, heavy-duty vehicles and sports cars may use polyurethane engine mounts instead for added stiffness. Manufacturers also use hydraulic-fluid-filled mounts in modern vehicles to further decrease vibration.

Shop now for engine mountsDepending on the motor’s size, your vehicle may contain three or four engine mounts. If you see an extra mount, it may be for the transmission instead. Your car’s service manual tells you how many motor mounts your vehicle has and shows you their positions.

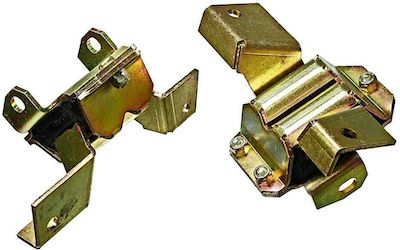

Hasport Honda Civic EK B-series engine mounts

Engine mounts have several purposes:

- Reduce engine vibration

- Limit engine noise

- Prevent damage to the engine

- Extend the life of the motor and sensors

The engine mounts absorb energy to prevent unnecessary damage. Because the mounts take the brunt of the vibration, they will wear down over time.

Symptoms of a Bad Engine Mount

Many of these symptoms resemble more critical issues, so they can be alarming. Here’s what to watch for.

Unusual Vibration

There’s always some level of vibration from the engine doing its job, but the purpose of the motor mounts is to damper this. When you know what’s normal for your vehicle, you become more aware when something is off, like more vibration. You may feel it immediately after starting the engine, or the vibration may become more pronounced while moving.

Energy Suspension 1964-1972 Ford V-8 engine mounts

Louder Engine Noises

With more vibration comes more noise. The additional engine noise is one of the most unnerving symptoms because it’s difficult to tell from the sound alone if it’s an engine problem or just a worn mount.

Rough Start

When everything runs smoothly, you won’t feel any unusual movement at startup. However, when a mount is failing, the car may try to lunge forward slightly after starting. Once you’re underway, the rough movement may transition to vibration. You may also notice this rough movement after taking off from a stop sign or light.

Clunking or Banging

When your car first moves, you may also notice a distinct clunking or banging sound as the engine shifts its position. You won’t be able to miss it, and it’s loud enough to cause alarm. When the engine moves inside the bay, it can come in contact with other vital parts, leading to further damage.

Noticeable Wear

The easiest way to spot a bad engine mount is to perform a visual inspection. Examine the mount for corrosion, warping, or cracks.

Reasons That Engine Mounts Wear Out

Every car and every driving situation is different. In some cases, motor mounts can begin to fail in five to seven years, where in others the engine mount can last the lifetime of the car. There are reasons for the engine mounts to fail prematurely. Here are some of the most common:

Megan Racing Lexus IS300 – 2JZGE motor mounts

- Age – Most mounts are made from rubber and aren’t designed to last the vehicle’s lifetime. Even with proper care, the mounts eventually wear out.

- Aggressive driving – Failing to use the clutch correctly or over-revving the engine means the mounts endure more stress.

- Fluid leaks – If engine oil or other fluids leak onto the mounts, the rubber can weaken. Over time, the material degrades and leads to excessive vibration.

- Accident – After a collision, damage can occur under the hood. It’s essential to inspect the engine bay after an accident.

- Poor installation – If new mounts aren’t fitted and secured correctly, more movement could occur.

Fixing a Bad Engine Mount

Damaged and broken mounts can’t be repaired. The only solution is to replace them. You don’t have to change all of the engine mounts simultaneously, just the damaged ones.

Inspect the other motor mounts for signs of damage. As they age, there’s a higher chance of warping or cracking.

Do not continue driving a car with bad engine mounts. Here are a few things that could happen as a result of ignoring the problem:

- Engine or component damage – Misalignment or movement of the motor eventually leads to massive failure. Bad mounts can cause damage to radiator hoses and other critical accessories.

- Increased chance of an accident – If the engine mount breaks while driving and the motor moves freely, it can drop road debris, creating a hazard for you and other drivers.

Replace bad mounts immediately to keep your repair costs as low as possible and ensure safety.

Engine Mount Replacement Cost

If you replace a bad engine mount yourself, you may spend $125 to $350 for the parts. Add professional labor into the equation, and the bill may rise another $200 to $300.

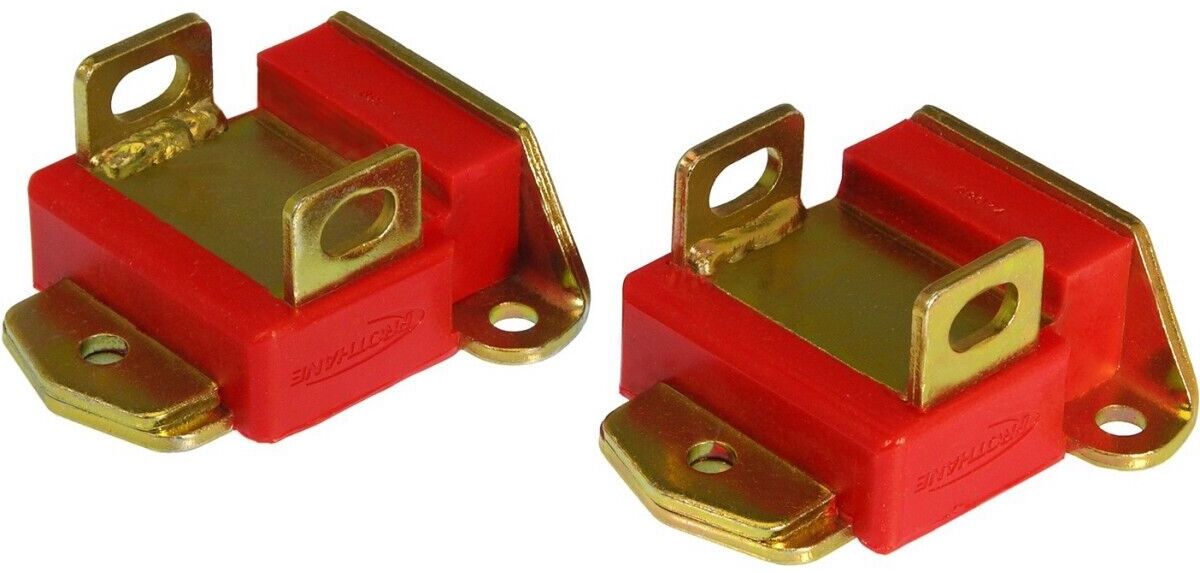

Prothane motor mounts – 1958-1982 Chevrolet

Many factors affect the actual price of replacement:

- Replacing several mounts costs more than swapping one out.

- The type of vehicle affects the part’s cost, with luxury models often costing more.

- If labor is required, your location affects the hourly rate.

Some engine mounts are also considered non-load-bearing, making them easier to replace. This type lets you quickly unbolt the bad mount without supporting the engine. If the mounts are load-bearing, they support part of the engine’s weight. These are more difficult to replace because the motor must be supported.

You must also consider how much room there is in the engine bay. Some vehicles have tight engine compartments, making installation much more difficult. You may need to remove other components to access the mounts.

Keep up with regular car maintenance to ensure the mounts remain in good condition.

Shop now for engine mounts