Contents

- Before the Gen III LS1 was released in 1997, the only substantial update to the small-block Chevy (SBC) engine was the Gen II LT1, which was a good engine (undermined by a poor placement of the ignition system).

- The LS platform shares almost nothing with the original small-block engine, continuously produced since 1955.

- Following the Gen IV LS was the Gen V LT-series, which is yet again completely different from the LS-series.

- There are two generations of LS engines, Gen III (1997–2007) and Gen IV (2005–2020). These two designs are very similar and share many components.

- Truck engines are referred to as “Vortec,” whereas the passenger car engines are “LS.” They’re the same engines with a few differences here and there.

What Makes the LS So Popular?

The benefits of an LS are clear: better fuel economy, significantly more power potential, and vast aftermarket support; plus, you can swap an LS into anything that can take an SBC, making it a simple choice.

A typical SBC 350 can handle 350 to 400 horsepower on the stock bottom end, whereas the 5.3 LS can double that in daily use and triple it for occasional blasts down the strip with lots of boost. The LS is the engine that made 1,000-horsepower attainable for the average gearhead. In the early 2000s, the benchmark for a high-performance V-8 was 500 horsepower, but now you can get 500 or more with a tune and some bolt-on parts.

Learn: How to Get Started with an LS Engine Swap

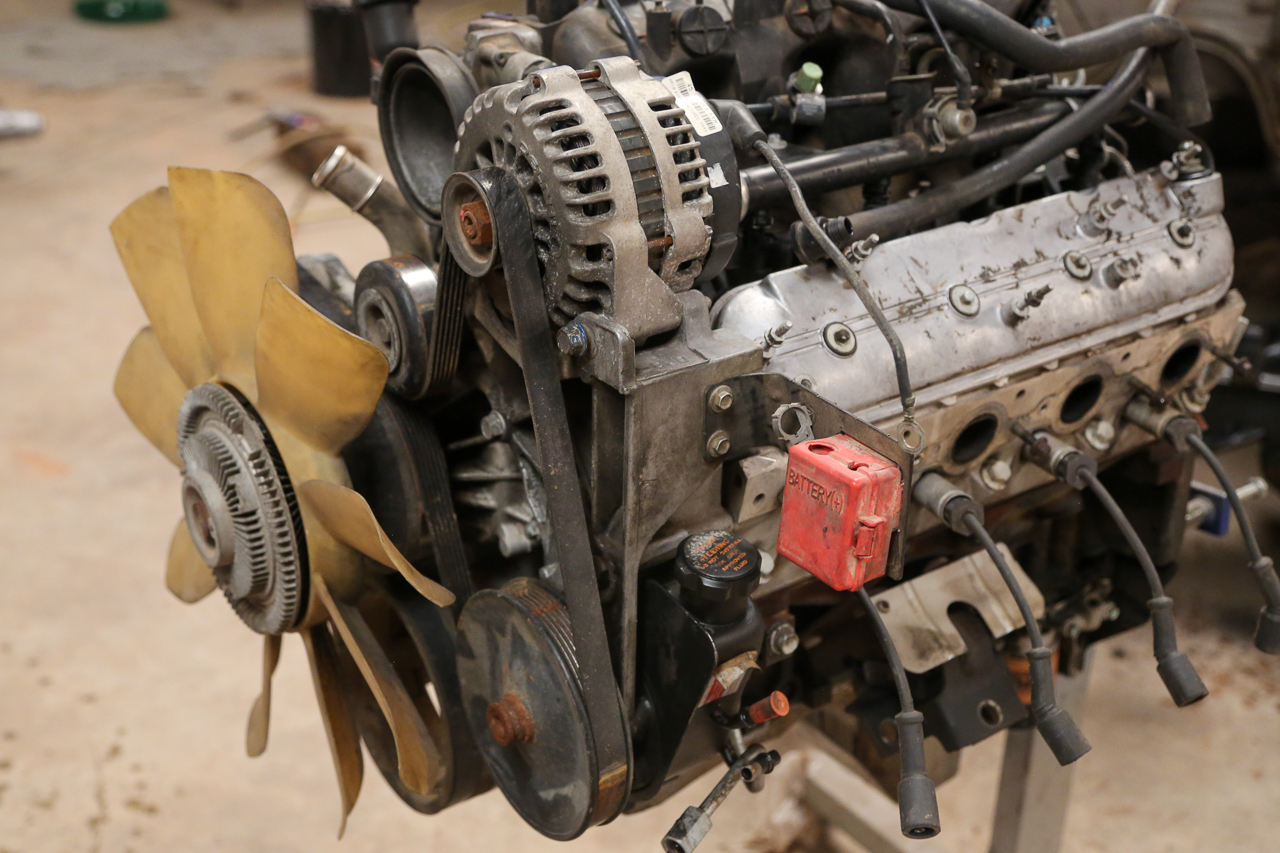

This LM7 is ready to swap into a vintage Suburban. The near 300HP Vortec will replace a wheezing SBC.

The typical fuel economy for a 350 ci SBC is 8 mpg city and 15 mpg highway, whereas the standard for a 5.3 LS is 12 city, 18 highway. This can go up and down based on transmission, gearing, and engine performance. Still, even at high-performance levels, an LS can often manage better efficiency over a stock 350 SBC and make much more power while doing it.

Shop now for LS V-8 drivetrainsInside the LS Engine

All LS car engine blocks were cast aluminum. Most Gen III truck engines were cast iron, but some were cast aluminum. All use the standard 4.4-inch bore spacing like the original SBC, and all are pushrod-type with block-mounted cams. For Gen III LS engines, the iron-block Vortecs are stronger than their aluminum-blocked LS brethren. Gen IV aluminum blocks are stronger than Gen IIIs and are preferred for their lighter weight (100 lbs on average).

A look inside the 150,000 mile LM7. The engine is rebuildable with standard machine shop work despite poor maintenance.

Cylinder Heads

LS and Vortec engines have aluminum cylinder heads, except for the LQ4, which has iron heads. Most LS engines use cathedral port heads with tall, skinny intake ports. The Gen IV LS3/L92 uses rectangle port heads, which flow incredibly well and are used in most high-performance Gen IV models. For the LS7, GM used rectangular ports, but they are wider and shorter than the L92/LS3 ports, and the castings were CNC ported from the factory. Any LS cylinder head can bolt to any LS block, but there are some issues—such as bore spacing and valve sizes—to consider. The LS intake manifold must match the intake port style.

Here is an LQ4 6.0L iron block with aftermarket aluminum LS2 heads. This engine made about 500 horsepower.

Crankshafts

All LS cranks use the same overall design and are nodular iron castings, except for the LS9, LS7, and LSA cranks, which are forged steel. Gen III cranks use a 24-tooth reluctor wheel for the crank position sensor, and Gen IVs use a 58-tooth. These are not interchangeable without changing the ECM and harness. However, the wheels can be switched on the crank to match your ECM.

Connecting Rods

LS rods are made from sintered powdered metal with cracked cap rods, meaning they only fit together one way. The only engines with forged titanium rods are the LS7 and LS9, which require matching LS pistons. The standard LS rod is good for about 1,000 horsepower briefly, but 600 horsepower is sustainable.

Pistons

If you plan on making 500 horsepower or more, upgrading the rod bolts is a good idea. Only the LS9 uses forged pistons. Every other production LS has hypereutectic cast pistons. Most are good to 600 horsepower as long as the engine isn’t detonating. Gen III pistons are press-fit to the rod pins, but Gen IV switched to floating pins, making assembly much easier.

Gen III LS engines use press fit pistons. Removal and replacement requires a special connecting rod heater.

Fuel Injection

All versions of LS engines use port injection, where the fuel enters via LS fuel injectors just above the intake runner in the head with a single throttle body on the front of the intake. Truck intakes are very tall and don’t clear car hoods well, but they provide the most low-end torque. Car intakes are lower, raising top-end horsepower at the cost of some bottom-end grunt.

ECMs

The electronic control modules vary by year. You can swap ECMs, but when you do, all the sensors and plugs must change to match the one you are using. The biggest key is the crank wheel: 24x and 58x. This is the main thing to keep straight. An easy tell-tale is that 24x crank sensors are black, while 58x are gray.

Shop now for LS engine componentsRPO Codes

There are about a bajillion versions of the LS and Vortec engines, so we will keep it basic here. All vehicle options, including the engine, are assigned a regular production option (RPO) code. When someone says, “I have an LS6,” that refers to the GM RPO code for that specific engine. LS6, LQ9, LSA, LM7—these are all RPO engine codes.

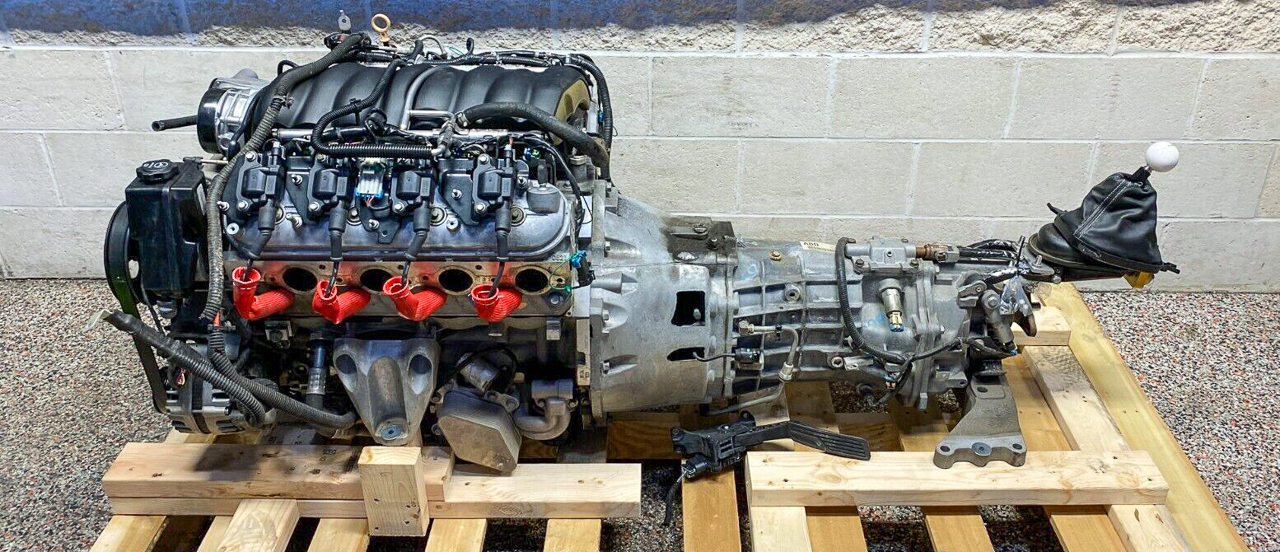

A ready-to-ship 6.2L LS3 V-8 and Tremec 6-speed manual transmission dropout from a 2010 Camaro

Most Vortec codes are L##, while most car engines are LS#, with a couple of random variants thrown in to make it confusing. The most popular RPOs for LS engines are LS1, LS6, LS2, LS3, LS7, and LS9, while popular Vortec RPOs are LM7, LQ4, LQ9, LR4, and LH8, though these are just a few of the variants. Vortec engines have a lot of RPOs, whereas there are just a few for the passenger vehicle LS-series engines.

Read: Why the Chevrolet LS9 is the Ultimate LS-Series Engine

Gen III

- LR4 – The baby LS at 4.8 liters, this Vortec engine is not to be dismissed. These are great for high-revving screamers, and they can make a lot of power for a short time with lots of boost. These are a dime a dozen in salvage yards and on eBay Motors.

- LM7 – There are a lot of 5.3 Vortec engines, but the most common is the LM7. Power ranges from 270 to 295 horsepower and 325 to 335 pound-feet. These are easy to find and build and the best way to get into a cheap LS swap.

- LS6 – The big dog Gen III made 385 horsepower and 385 pound-feet of torque, as it is an upgraded version of the LS1. GM eventually upped the power to 405 horsepower and 400 pound-feet.

- LQ4 – If you want a bigger LS, the LQ4 is a good option. GM stepped up to a 6.0 liter with the LQ4, and while horsepower is 300 to 325, the torque ranged from 355 to 370 pound-feet, as these are truck motors. These have iron blocks and aluminum heads for maximum durability.

- LQ9 – The Vortec HO or VortecMAX 6.0 made 345 horsepower and 380 pound-feet. Much harder to find than an LQ4, these high-compression engines tend to command a bigger price tag.

Gen IV

- LS2 – Built for the 2005 Corvette, the LS2 is a 6.0-liter all-aluminum V-8 making 400 horsepower and 400 pound-feet of torque.

- LS3 – One of the most desirable LS engines, this is a 430-horsepower, 424-pound-foot monster that first graced the 2008 Corvette. It is a 6.2L and is considered the best LS engine that isn’t an LS7 or LS9.

- LS4 – The only front-wheel drive LS engine, the LS4 is perfect for swapping into FWD chassis, making 303 horsepower and 323 pound-feet of torque.

- LS7 – The only production 7.0L 427 LS engine, the LS7 is a bad mamma jamma. Originally installed in the C6 Z06, this naturally aspirated 505-horsepower, 470-pound-foot beast can spin to 8,000 rpm. Each LS7 was hand-built, and while most were installed into Z06 Corvettes, a few made their way into the 2014 and 2015 Z28 Camaros.

- LS9 – The baddest of all production LS engines, the LS9 is a supercharged 6.2L that makes 638 horsepower and 604 pound-feet of tire-shredding torque. The only model to receive this engine in production was the 2009 to 2013 C7 Corvette ZR1.

- L92 – The top dog Vortec Gen IV engine is the L92 6.2l. Making 403 horsepower and 417 pound-feet of torque, the L92 came in higher-end GM trucks, SUVs, and the H2 Hummer.

The Advent of the LT Engine

In 2014, GM released the Gen V LT-series engine with three new V-8s. The LT1, L86, and L83 are direct injection engines where the fuel no longer flows through the intake or heads. Instead, fuel is injected directly into the combustion chamber, giving the ECM ultimate control of every aspect of operation. The drawback of direct injection is that the fuel side of performance upgrades gets expensive, whereas upgrading all parts of the LS-series engine is very cheap.

The 5.3L Vortec (left) and 2015 Gen V 5.3L L83 (right) are similar but only share rods, crank bearings, and a few bolts.

The LT1 is a 6.2l V-8 making 460 horsepower and 465 pound-feet of torque, while the L86 truck version pumped out 420 horsepower and 460 pound-feet of torque. To fill the smaller V-8 need, the L83 5.3l makes 355 horsepower and 383 pound-feet, better than most every 5.3L LS-series engine. Gen V engines share the same bellhousing pattern as LS engines but have different motor mount positioning and bolt patterns. The aftermarket gravitated to the LT series faster than the LS, and the LT swaps crept into the hot-rodding world much faster, too.

Should You Do an Engine Swap?

At some point, most gearheads consider an engine swap. This used to be a daunting task, considering the intricacy of making a different engine work in something it wasn’t designed for. The LS engine was the peak of that difficulty in the beginning, as the EFI electronics were confusing. The aftermarket has solved that issue a hundred times over; you can even buy entire swap packages that make it a simple bolt-in and plug-in installation for many vehicles.

Shop now for LS swap partsIf you want to upgrade your classic muscle car, truck, or whatever, the LS (and LT) engine is a good option. They are affordable, easy to swap, easy to rebuild, and last for 300,000 miles if you take care of it.