Contents

What Is a Wheel Bearing?

Rear-wheel-drive (RWD) vehicles typically use two front bearings and one rear bearing per wheel. The front bearings are a cone-shaped assembly of roller bearings in a steel frame.

The bearing rollers are in direct contact with the spindle shaft (the part that connects to the suspension) with an inner and outer bearing and an outer race that is pressed into the rotor hub. This style is also sometimes used in front-wheel-drive (FWD) applications for the rear wheels.

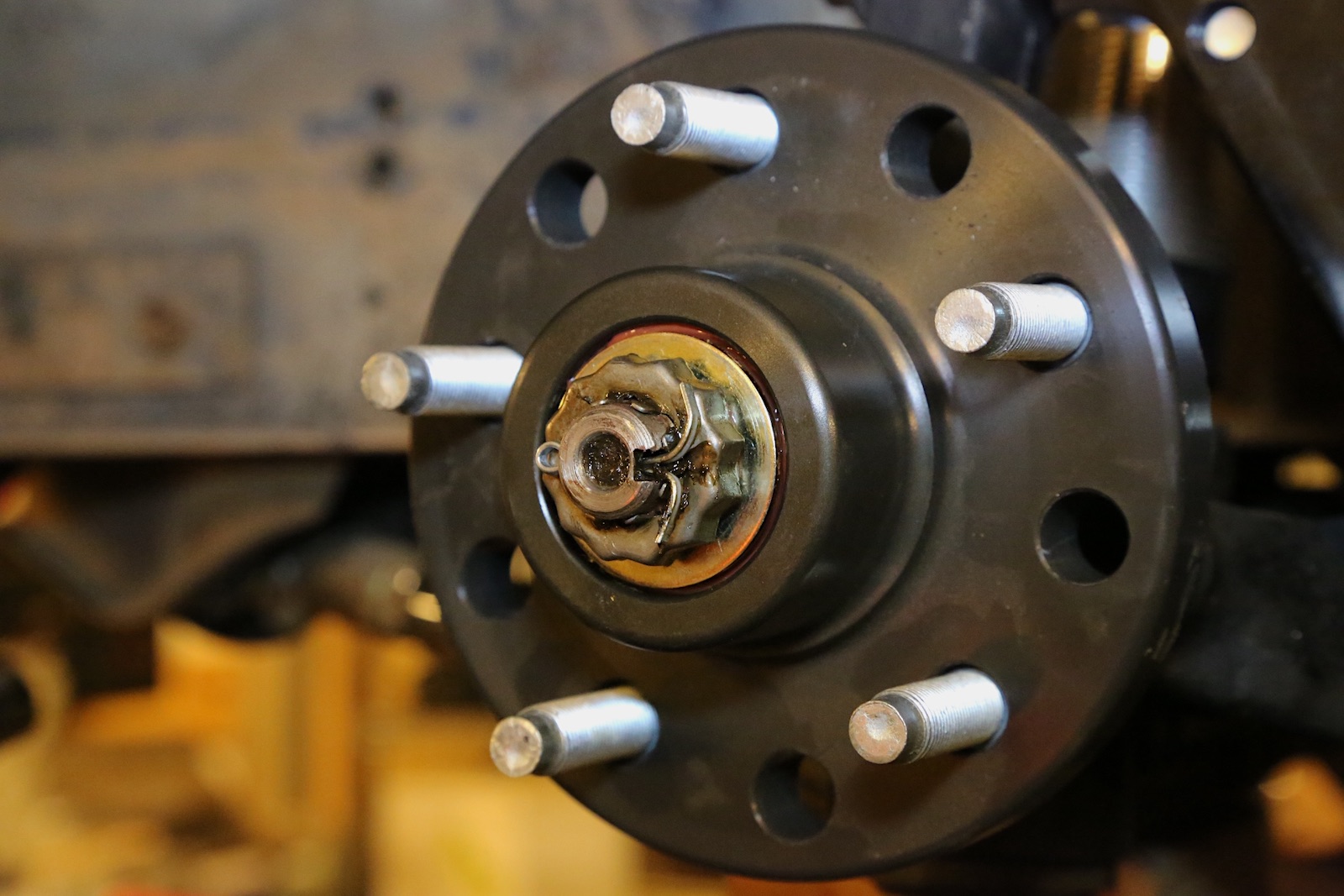

This is a wheel spindle for a non-drive wheel, specifically a 1960s Mercury Comet Wagon. This is what most RWD vehicles have up front. Some FWD vehicles and trailers use this in the rear. These bearings are easily serviced. The other types are typically sealed. (Photo: Jefferson Bryant)

Front-wheel drive vehicles and RWD and AWD vehicles with an independent rear suspension use a different wheel bearing style. These are flat or horizontal roller bearings mounted into the wheel hub or spindle itself.

Straight-axle rear wheel bearings are another type of bearing. These are typically pressed onto the axle shaft and are not sealed, so they are lubricated with the rear axle gear oil. These are more difficult to replace than non-drive front bearings (because you need a large press) but easier to replace than drive-hub-style bearings.

Symptoms of a Bad Wheel Bearing

The primary sign of a bad wheel bearing is noise. Bearings don’t wear out instantly, so the first thing you’re likely to notice is a low humming from the wheel in question. The pitch and volume of the noise will change with vehicle speed.

Behind the dust cap, there is a cotter pin and a castle nut. The smaller outer bearing is behind the large washer under the castle nut. (Photo: Jefferson Bryant)

As the wear grows, the hum turns to a loud groan, growl, or howl. You should be able to easily discern which wheel is making the noise. Bearings on straight-axle vehicles can be hard to hear as they start to wear because they are cased inside the axle housing, so the howl may be the first thing you hear.

Drive hubs for front or rear independent suspensions may click when reversing or accelerating in a straight line. CV joints click and howl when they are failing, too, so a key telltale is when the sound appears. If the sound occurs only when turning, then it is likely a CV joint and not a bearing, but do a physical check to know for sure.

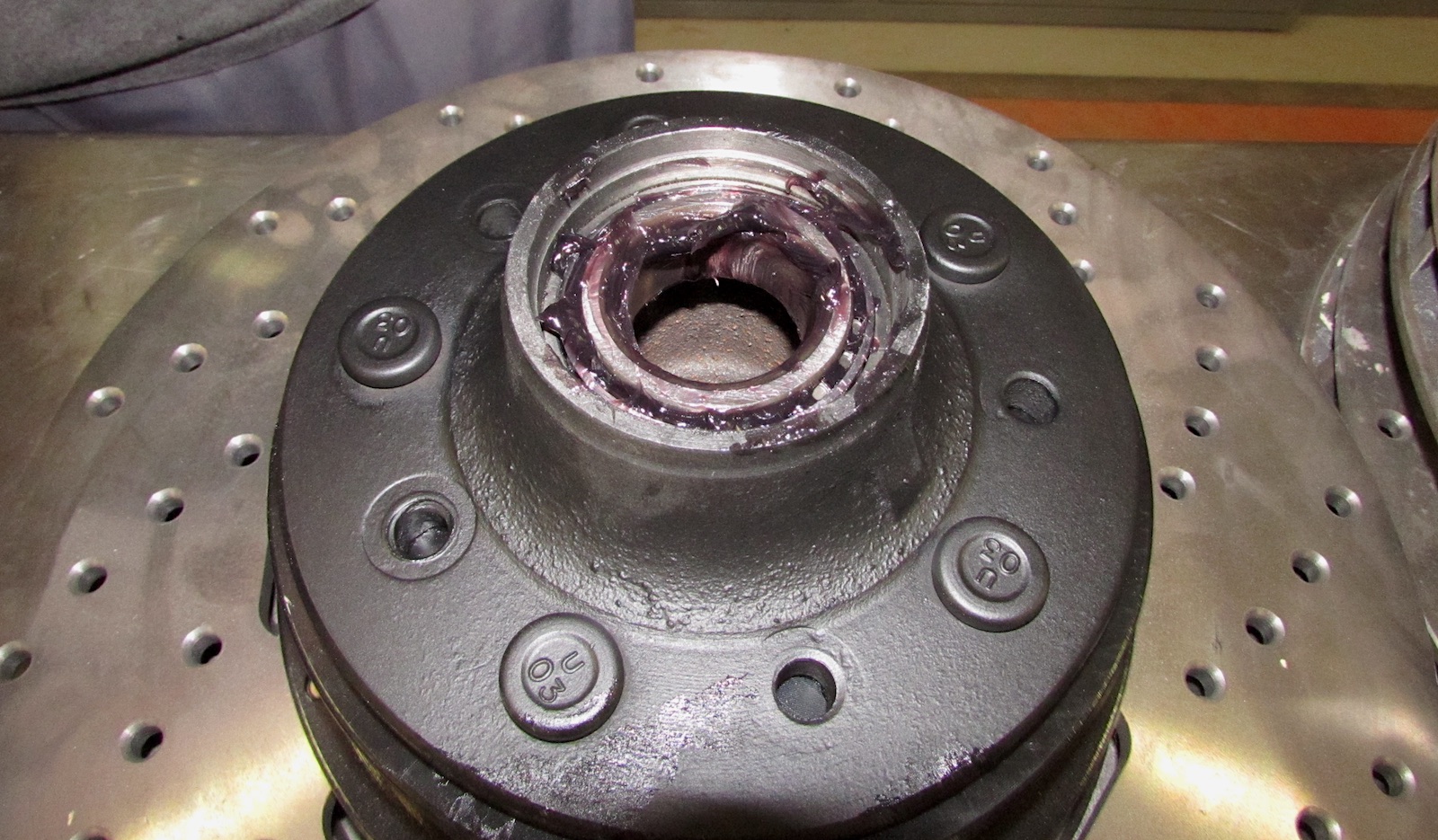

Replacing these wheel bearings is relatively simple, but they need to be packed with grease. (Photo: Jefferson Bryant)

Once the wear is bad enough, the ABS light will likely illuminate on the dash. This is because the bearing is so far out of spec that the wheel hub is not spinning squarely. Other issues can trigger an ABS light, but if you have the hum or howl plus the ABS light, you are likely facing a wheel bearing failure.

Other signs can point to a wheel bearing problem, such as uneven tire wear, loose steering, vibrations, and pulling to one side, but these are also signs of other issues. Most bearings make noise before the other symptoms are noticeable.

Shop now for wheel bearingsThe Wobble Test

If you hear the hum or howl, an inspection is needed. The best way to check a wheel bearing is the wobble test:

- With the vehicle in a safe location and the engine off, raise each corner of the car with a jack one wheel at a time and set jack stands in place.

- Hold the top and bottom of the wheel and press in at the top. The wheel should not move.

- If the wheel wobbles from top to bottom, the wheel bearings are failing and need servicing soon.

Straight axle wheel bearings are similar. There should be little to no vertical movement in the axle. A telltale sign of rear axle bearing failure is gear oil on the tire.

Cost to Replace Wheel Bearings

The cone-shaped bearings on RWD vehicles are easy to grease as part of your routine maintenance schedule. They are relatively cheap to replace. Most bearings are less than $20 each.

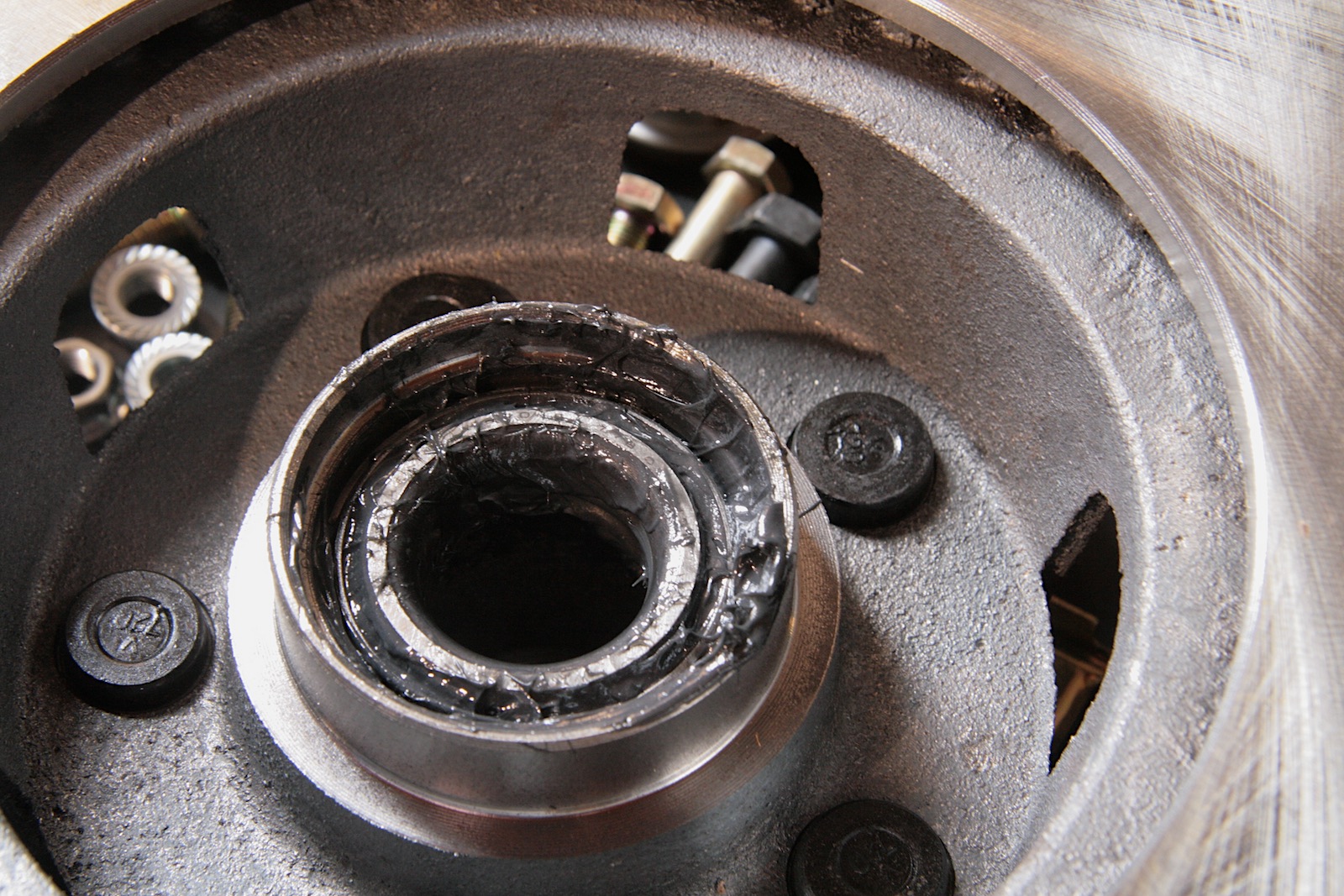

The inner bearing is larger as it supports the bulk of the weight. A press-in seal keeps water out. (Photo: Jefferson Bryant)

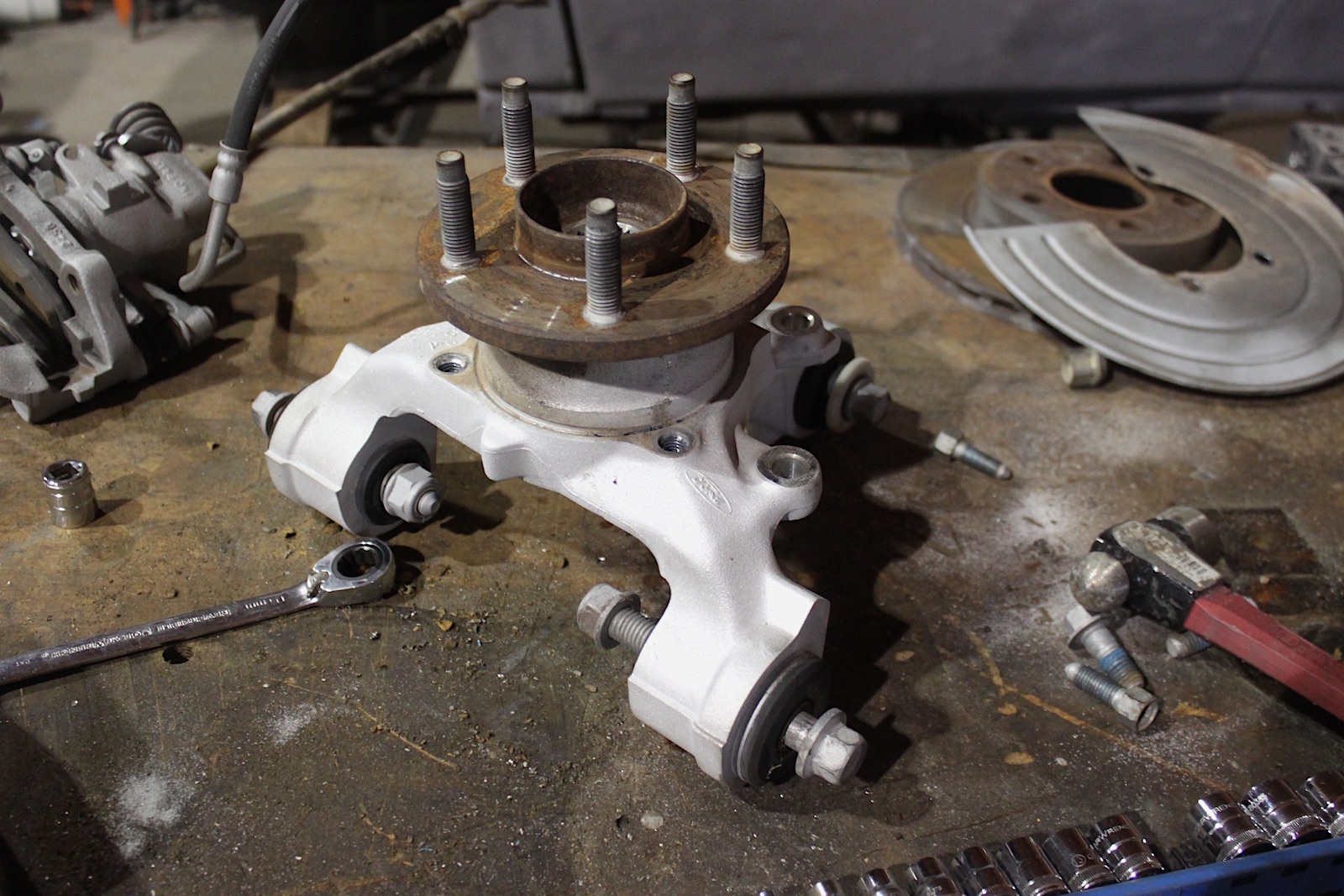

The horizontal bearings used on FWD vehicles and those with independent rear suspensions are usually sealed bearings, meaning you can’t grease them as part of a maintenance schedule. They are user-replaceable, but this requires replacing the drive hub and, in some cases, the steering knuckle, which is more expensive.

The average FWD or independent-rear-suspension RWD wheel hub costs about $120, but they can run much higher depending on the make and model. Replacing these hubs may also be involved, particularly in the case of four-wheel-drive trucks and SUVs, where the entire steering knuckle must be replaced.

Wheel Bearing Failures

If the bearing gets bad enough, you can have brake lockup, rotor breakage, a severely worn hub or spindles, or broken hubs or axles. The wheel can literally come off the vehicle, putting you and everyone around your vehicle in serious danger. Even if the wheel stays on, a major failure can put the vehicle out of control.

FWD, AWD, and IRS (independent) RWD vehicles use hubs like this mid-1990s Ford Thunderbird hub. The rotating hub (with the wheel lug studs) has a replaceable roller bearing. Many modern vehicles require replacing the entire hub or knuckle. (Photo: Jefferson Bryant)

If the bearings seize, you will have a really bad day. The wheel bearings are the only thing keeping your wheels spinning. They are critical for your vehicle and should be treated as such.

There is no general rule for wheel bearing replacement. They may last 50,000 or 200,000 miles. It depends on the make, model, and type of service. Stop-and-go driving is harder on the bearings due to short-term heat cycling, and heavy loads and hard terrain can shorten the life of your wheel bearings.

In the vehicle, you can see why these are more difficult. The axle shaft engages the hub directly, so the bearings are much larger than the non-drive style. (Photo: Jefferson Bryant)

The best way to know when they are failing is to occasionally roll down the windows, turn off the radio and air conditioning, and listen. You should do this regularly. Catching a bearing issue early is the best way to avoid other problems.

Shop now for wheel bearings