Contents

There are two main components to power steering:

- The pump, which is bolted to the engine and driven with a belt

- The steering gear can be a gear-recirculating ball (for older vehicles) or rack and pinion.

Sometimes, power steering issues lie with the steering gear, but most of the time, it’s the pump.

Symptoms Of A Bad Power Steering Pump

Noise – The first sign of an issue could be a groaning or growling noise from the pump. Most pump noise is due to air leaks or low fluid. Your system may have a remote reservoir or a tank-mounted reservoir. Pop the cap and check the level. Some caps have a built-in dipstick. With the engine off, the fluid should be close to the top of the reservoir. As the engine runs, the fluid should swirl about half to three-quarters capacity.

If you see bubbles or foam, the system has an air leak. The most common cause of air leaks is improper hose connections.

If you can access the bolts, some pumps can be removed or installed with the pulley on. If the pulley is solid, then you likely need to pull it to remove the pump. Most V-belt pumps can be removed with the pulley on.

Leaks – Power steering fluid is red. It looks and smells like transmission fluid because it is essentially the same thing. (In a pinch, transmission fluid can be used in most power steering systems).

Check the fittings and hoses if you notice a red puddle under your vehicle. You can use brake cleaner to clean the engine, pump, steering gear, and lines. Then, run the engine and look for where the fluid begins to come out.

The hose connections are the most common cause of leaks, but the lines can get worn from rubbing or road debris, causing a hole in the line. If overfilled, a pump can leak around the pulley shaft or from the reservoir. Rack and pinions can leak at the head (where the column and lines attach), along the lines that run across the rack itself, and out of the bellows that protect the moving parts.

Loss of assist – Once you lose assist power, you have a real problem. If you do not have any leaks, the problem is usually the pump. Most pumps sometimes make noise before they die. Pop the cap on the reservoir and start the engine. The fluid should swirl slightly inside. If there is no movement, the pump is not pulling fluid and needs replacing.

Replacing a Power Steering Pump

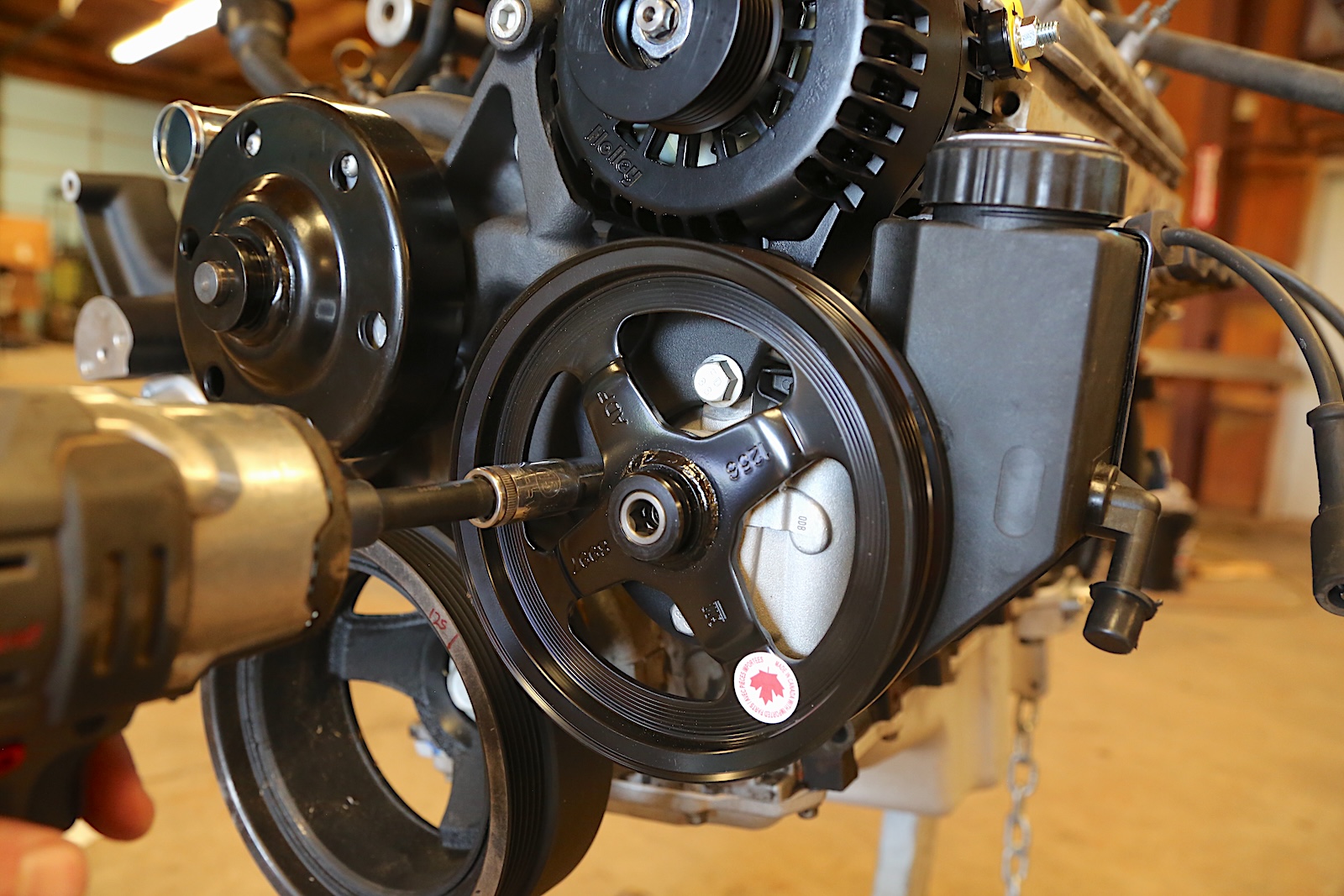

Power-steering pulley tool kits like this work for installing all pulleys and removing clamshell-type pulleys. The tool on the left is the installer, and the middle assembly is the clamshell-type remover. These kits are universal.

Most of the time, you are better off replacing a power steering pump rather than rebuilding it. You can buy rebuild kits, but critical adjustments are required to ensure correct pressure. For the average DIYer, replacement is the best option.

To replace a pump, you need a few tools:

- Socket set and ratchet

- PS pump pulley tool

- Breaker bar or pry bar (to release the belt)

- Wrenches for the pulley tool

- Line wrenches

1. Remove Belt

First, remove the belt from the PS pump pulley. This can be a single-item or serpentine belt, depending on the engine. Take a picture of the routing so you know how to put the belt back on.

2. Disconnect the Lines

The sequence for the next two steps depends on your specific engine. Some require removing the pulley first, while others require the pump to come off first (if at all). Check a repair manual for details about your specific vehicle.

If first disconnecting the lines, use a line wrench to disconnect the pressure. Return the line from the pump and drain the fluid. Your return line is not high-pressure, so some vehicles use a simple hose clamp to secure the return line to the pump.

The pulley installer pushes the pulley onto the shaft with two wrenches. Clamshell removers are used in the opposite direction.

When replacing a power steering pump, the system must be flushed to remove any metal or contaminants. Brake cleaner works well to flush the lines. Have an assistant turn the steering wheel (entirely from one side to the other) while you spray the cleaner into the lines until it flows cleanly from the other hose. If you have a remote reservoir, flush this as well.

If your vehicle has filters inside one of the lines, check and replace those filters. This is an excellent time to check the condition of the lines and replace them as needed. Power steering systems generate over 2000 psi, so the lines are critical to proper operation. Minor surface abrasions on the lines are okay, but investigate the cause to ensure they don’t worsen.

If the lines have nicks, melts, pinches, or swelling, they should be replaced immediately.

3. Remove Pulley

In most cases, you will reuse the original pulley. Power steering pulleys are engine-specific. The diameter of the pulley determines the speed of the pump, which helps determine the pressure level of the system.

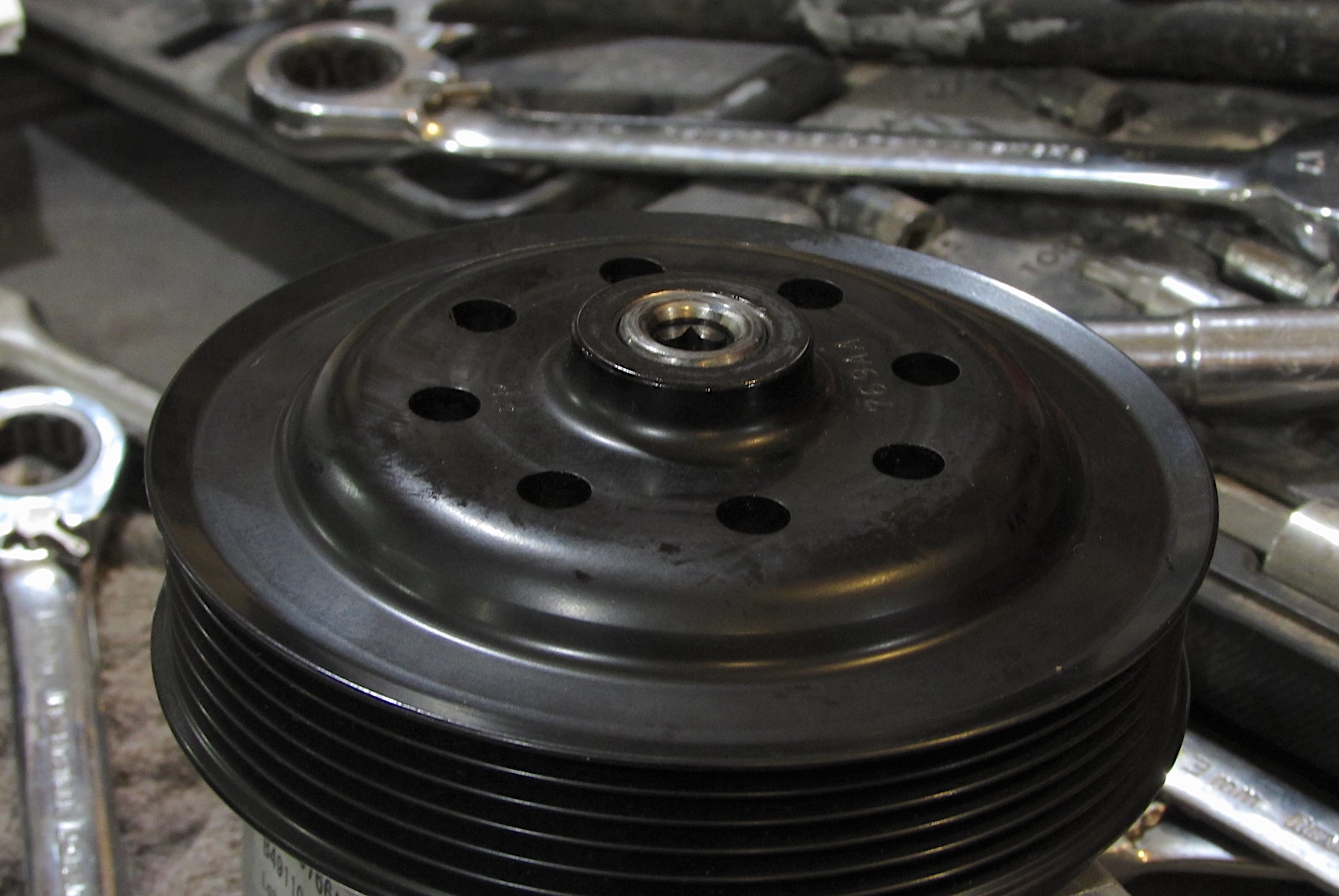

Tools to remove the power steering pulley are usually clamp-on or bolt-on. Most engines today use clamp-on pulleys. There is a small snout with a groove at the end of the pulley. The clamp-on tool slides over this snout with a clamshell, and a ring slides over the clamshell, keeping it from falling off. Then, the center stud threads into the pump shaft, and the clamshell assembly is threaded counterclockwise, pulling the pulley off the pump.

The center snout of this pulley is grooved. This is a clamshell-type pulley.

Most pulleys are friction-fit. However, some pulleys use a key to keep the pulley from spinning. If your pump has a key, save it in a safe, familiar place.

Bolt-on pullers use two to three bolts installed through a bracket with a threaded rod in the center. These tools are generally multi-use pullers for gears, steering wheels, and pulleys. They operate the same way as the clamshell puller but bolt to the pulley instead.

4. Remove Power Steering Pump

Most pumps have two or three bolts holding them to the bracket. Remove these and save them for reuse. Some pumps are front-mounted, but most slide into their bracket from behind. You may need to remove the larger bracket to get the pump out.

5. Install Pulley

Most pulleys require a pulley installer tool, part of the clamshell-type kit. This tool threads into the pump shaft with a large bearing threaded on the tool stud. Use two wrenches. The bearing head is threaded towards the pump, pressing the pulley onto the shaft. When the tool stops turning, the pulley should be flush with the shaft. This is the installed position.

6. Install New Power Steering Pump

Installation is the same as removal but in reverse order. After the power steering pump is installed completely, refill the reservoir with a new power steering fluid that meets the manufacturer’s specs for your vehicle. Some automakers, such as BMW, require specialty fluid. Verify the fluid type in your owner’s manual. Don’t use a fluid that is not the specified product. Damage can occur.

Most power-steering pulleys are pressed on until the shaft is flush. This is fully installed.

When the reservoir is full, start the engine with the reservoir cap off. Turn the wheels (lock to lock) about 20 times to bleed out the air in the system. Check the fluid level and refill the reservoir to the full mark.

Installing a new power steering pump is straightforward and relatively easy for most DIYers. The key to proper replacement is correctly flushing the system.

Shop now for power steering pumps