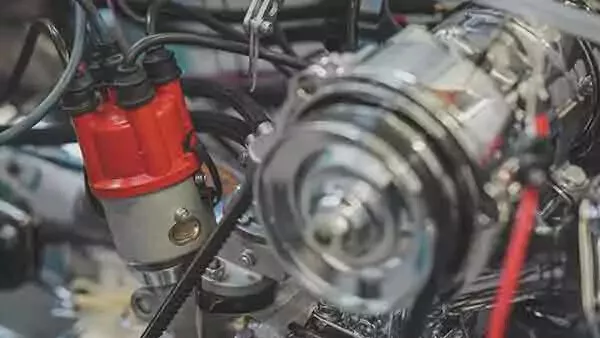

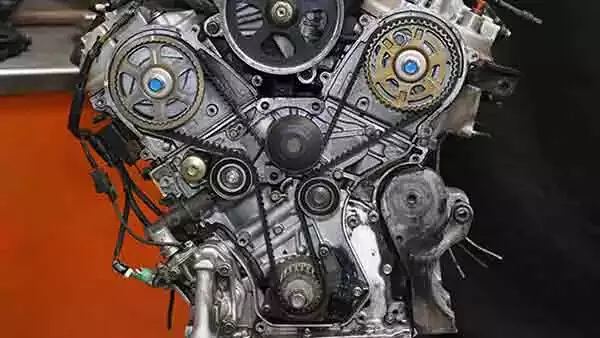

The ignition systems of engines built before 2000 often have a distributor. The distributor is driven from the engine’s camshaft, which spins a rotor—also called a rotor bug or rotor button—inside the cap.

There is a brief electrical connection when the bug sweeps past each spark plug terminal. That allows the spark to jump from the ignition coil to each spark plug. Over time, the contacts on the cap and rotor wear out, increasing the space between the two terminals. The extra space can result in misfires.

Replacing the cap and rotor is commonly part of a tune-up. Most manufacturers recommend a tune-up every two years or 30,000 miles.

Tips and Tricks

- Distributors can be difficult to reach on some vehicles. That adds time to the replacement process.

- Remove and replace the plug wires one at a time and use a damp rag to wipe them clean.

The first step for many auto repair jobs is disconnecting the vehicle’s battery. It’s a simple task. Remove the ground clamp from the battery’s negative post. Plus (+) and minus (-) signs are usually molded into the plastic battery case near the post.

Removing the negative terminal first ensures the vehicle is no longer connected to a live battery. This prevents sparks, electrical shorts, or components (such as fans) from unnecessarily coming on.

Pull the terminal off the battery for a close inspection. If there is corrosion, loose wires, or physical damage, consider replacing the battery terminal or cable.

Move the terminal away from the battery into a position where it can’t accidentally touch the battery post.

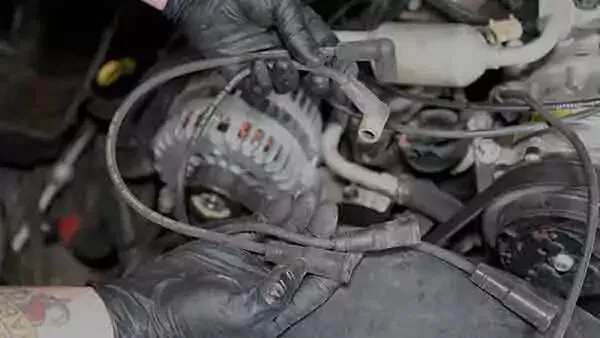

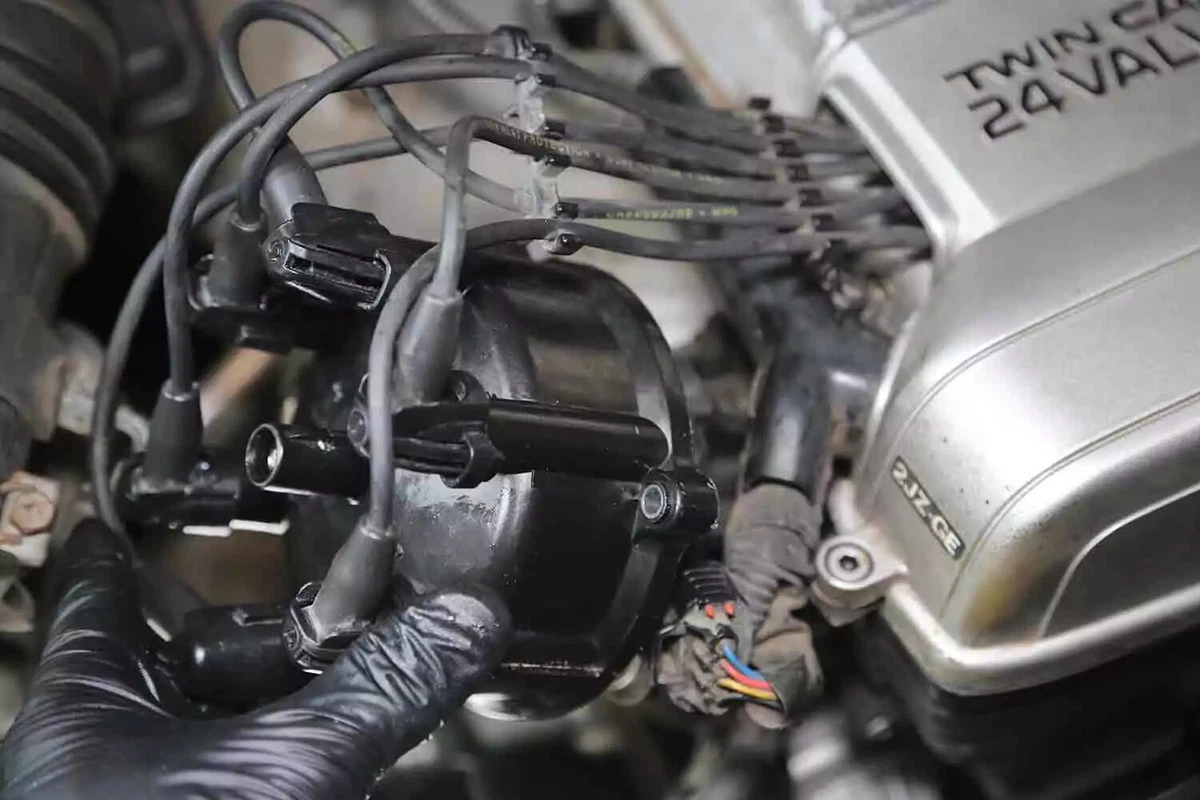

Mark each plug wire with a piece of masking tape. To confirm the correct plug position, trace each wire from the cap to the spark plug.

Remove the distributor cap fasteners. They might be screws, bolts, or spring-loaded locking pins. Most caps have two or three fasteners.

Remove the distributor cap from the distributor. We recommend removing the coil wire first so you have more flexibility to move the cap.

Note the #1 plug wire position in relation to the distributor. The #1 position will be the same on the new cap.

Examine the new and old caps next to one another. Most caps have an indexing tab to locate its correct position. However, our demo vehicle uses offset bolt spacing for positioning.

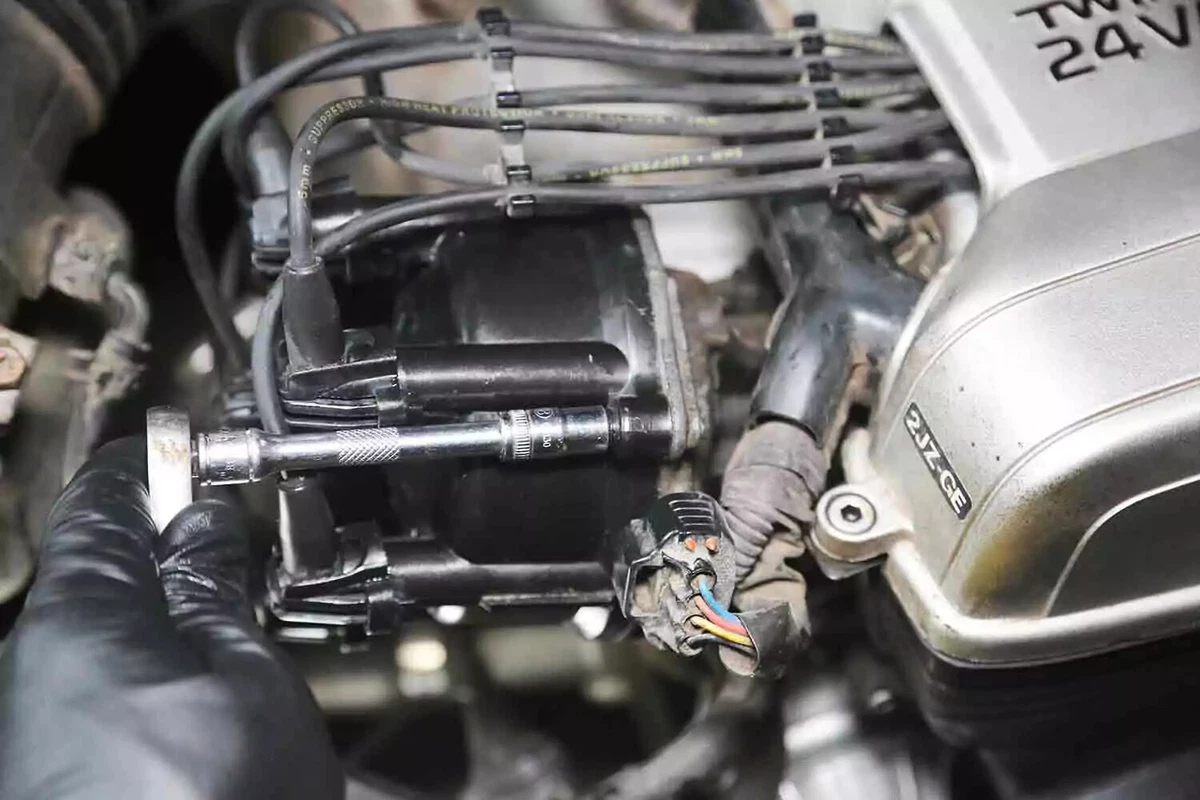

Remove each plug wire one at a time. Add a bit of dielectric grease to the plug wire boots.

Install each wire to the matching position on the new cap. Set the old cap aside after all wires are transferred and you attach the center coil wire.

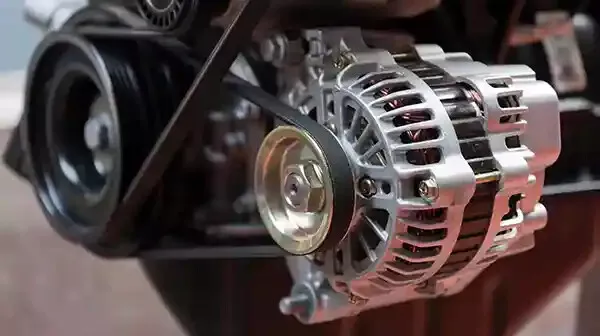

The rotor is in the distributor’s center. Some rotors slide off, while others have one or two fasteners to be removed. This one has two Phillips-head machine screws.

Use the correct tool to remove the fasteners. Some rotors come with new fasteners. For our rotor, we reused the original screws.

Remove the rotor.

Compare the new rotor to the old one. Make sure they are the same.

Install the new rotor. Most rotors are indexed so they cannot be installed backwards.

The shaft is D-shaped or has a tab-and-slot to ensure a proper fit. Spin the rotor on the shaft until it seats completely.

Install the new cap over the distributor, making sure that it is correctly oriented. Rotate it slightly until the tab-and-slot seats or the bolt holes line up.

The cap only fits and fastens properly when rotated to its correct position. As you seat the cap, rotate it slightly back and forth to line up the bolt holes or drop the indexing tab into its corresponding slot.

Install and tighten the fasteners. Hand tight is adequate. Overtightening the fasteners could crack or warp the cap.

Reconnect the negative battery terminal.

Share your feedback

This article is meant to provide general guidance only. Automotive maintenance, repair, upgrade, and installation may depend on vehicle-specifics such as make and model. Always consult your owner's manual, repair guide for specific information for your particular vehicle and consider a licensed auto-care professional's help as well, particularly for advance repairs.