Most vehicle manufacturers switched from V-belt accessory drives to serpentine drives in the early 1990s.

- A V-belt drive uses as many as five to six belts to connect each accessory to the crank pulley.

- A serpentine system has one long belt that connects all or most of the accessories to the crank pulley.

V-belts work well but are complicated to service. The serpentine system is easier and uses an automatic tensioner, which eliminates the need to adjust the tension on each belt.

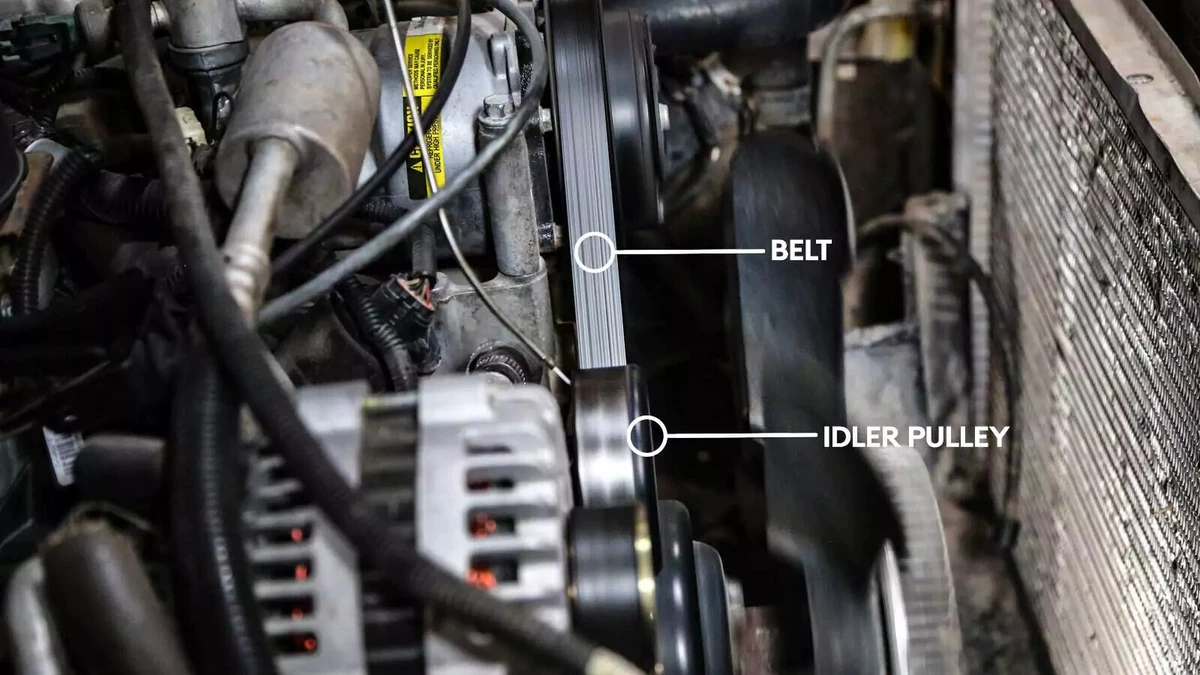

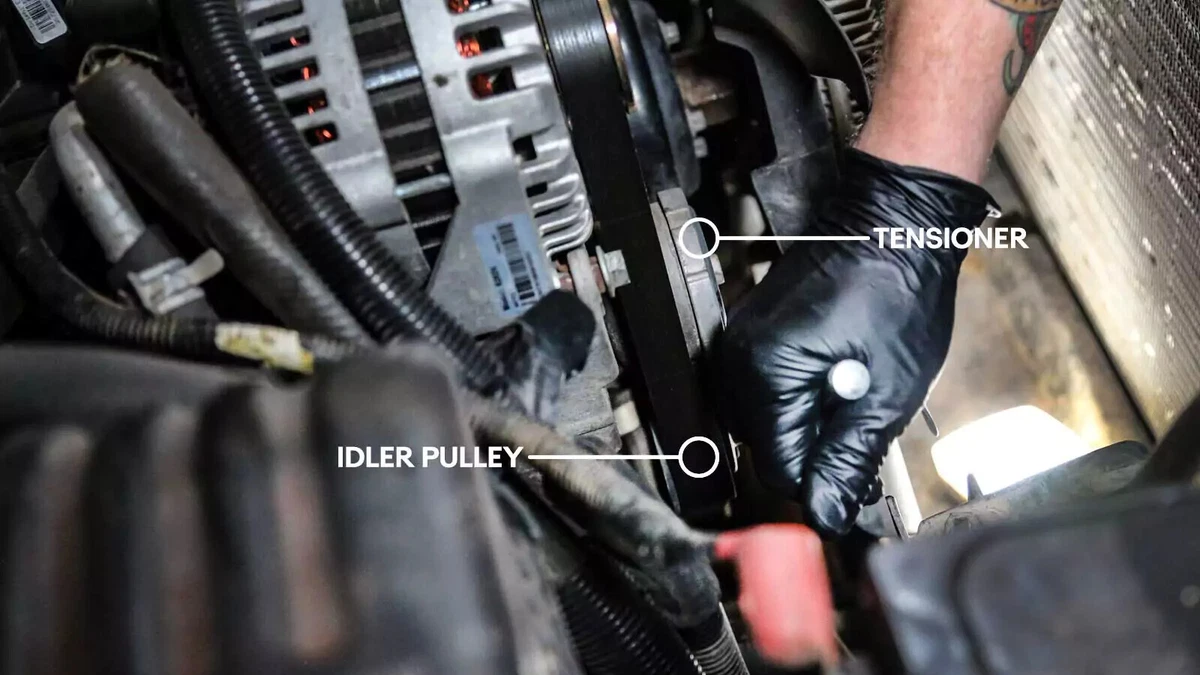

In addition to the accessory pulleys and tensioner, many engines also have one or two idler pulleys. These are used to redirect the belt’s routing around objects or to ensure enough of the belt is wrapping the accessory pulley for it to function.

How long does it take to replace an idler pulley?

Like many other parts, the idler pulley will eventually fail if used beyond its intended service life. Replacing your vehicle’s idler pulley is a quick, beginner DIY job on most vehicles. It usually takes 30 to 60 minutes. See our idler pulley buying guide - opens in new window or tab..

Tips and Tricks for DIY Idler Pulley Replacement

- The most common sign of a failing belt or pulley is an unpleasant sound. As the bearings inside the idler pulley wear out, they groan and squeal.

- You can test engine pulleys by spraying the bearing side with penetrating fluid. If the squealing briefly stops, you found the cause.

- When you replace the idler pulley, you should also replace the tensioner and serpentine belt.

- New tensioner arms include a new idler pulley. But your engine may also use a second idler pulley. If so, consider changing them both.

- This job involves removing the serpentine belt. The specific belt routing is usually noted on the hood or the radiator support cover. Before removing the belt, take a photograph of the belt routing for reference.

- If your vehicle doesn’t have a spring-loaded tensioner, you can release the belt tension with the adjuster on the alternator bracket.

The idler pulley is not connected to an accessory. Its location can be anywhere on the accessory drive. On our demo vehicle, the idler is at the top of the serpentine belt system, just above the water pump.

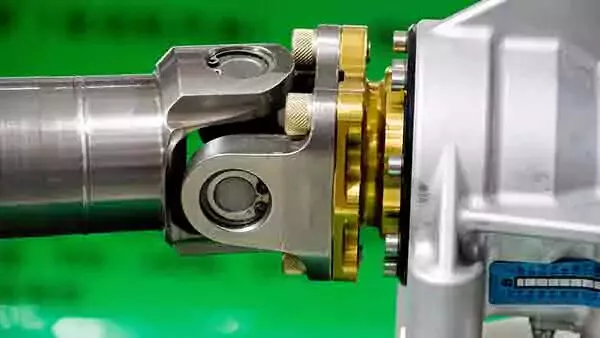

Using a breaker bar or socket and wrench, release the tension on the belt tensioner assembly. Some tensioners use a ½-inch or ⅜-inch square drive, which fits a ratchet or breaker bar without needing a socket. Others require using the bolt on the pulley.

Some vehicles use a Torx-head for the tensioner, which requires a special Torx socket.

If there is no obvious attachment point, check your owner’s manual.

While holding the tensioner to allow some slack for the belt, slip it off the idler pulley. If you're replacing the belt, remove it now.

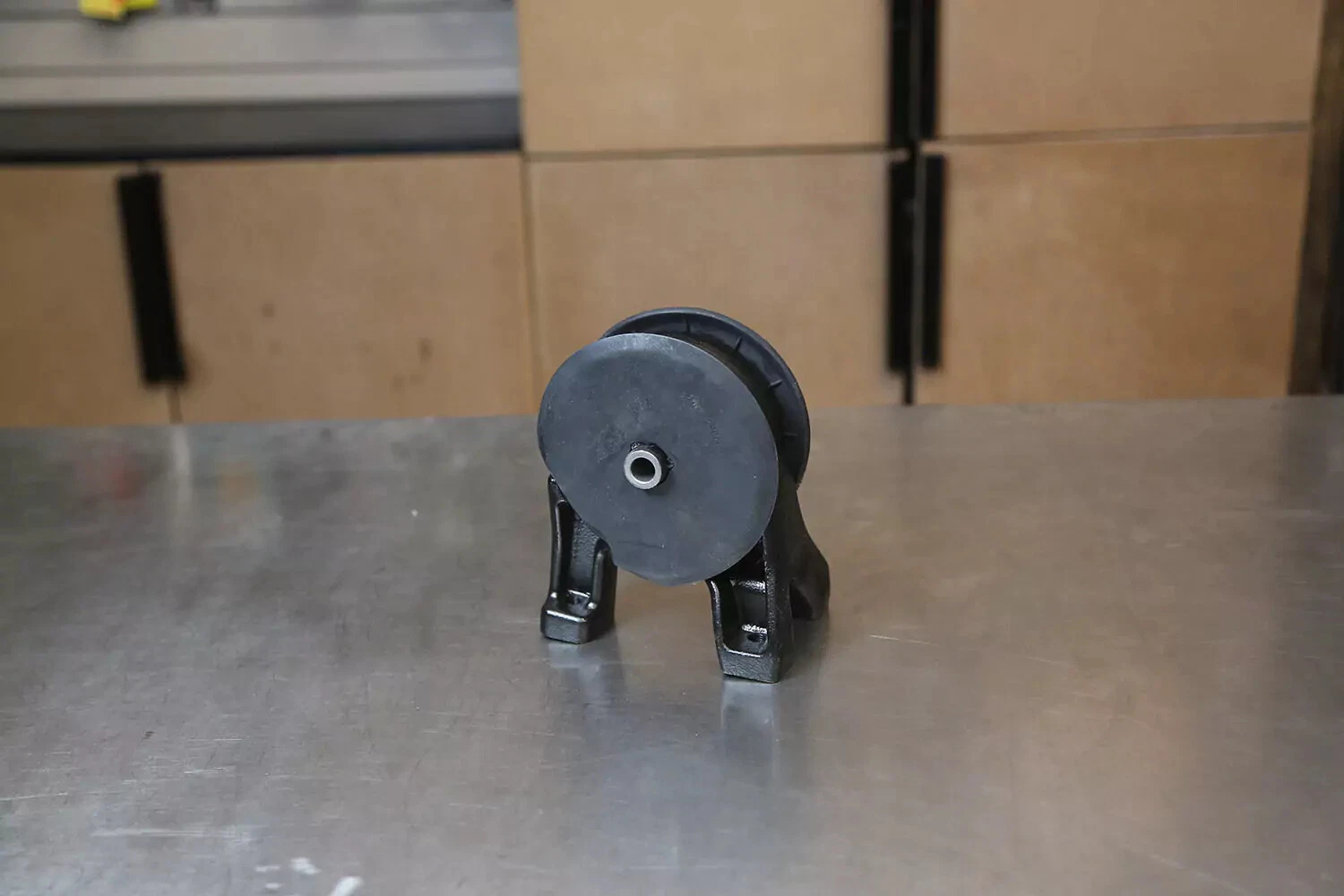

Most idler pulleys connect to the engine with a single bolt through the center of the pulley.

Some engines have a separate mount assembly that is replaced with the pulley. Our demo car doesn’t use one.

Remove the mounting bolt. Slide the pulley off the engine.

On our demo vehicle, a keeper ring holds the idler pulley bolt onto the pulley. Bolt keepers are difficult to remove intact.

Lift one edge with a pick. If it doesn’t come off easily, snip the ring with a pair of wire cutters.

Depending on your engine, you may need to reuse pieces from the original pulley. On our demo vehicle, we reused the bolt and a small spacer on the back of the pulley bearing. The keeper ring is there to hold the assembly together during installation at the assembly plant. You don’t need to reinstall the keeper.

Assemble the new pulley with any spacers or washers that were on the original.

Install the new pulley assembly to the engine, reversing the steps you took to remove it.

Do not forget any washers or spacers. They are required to position the pulley correctly and to keep it in place.

Use a torque wrench or torque gauge adapter to tighten the bolt to the correct specification. See your vehicle’s repair manual for details.

Do not overtighten. In most cases, the pulley is bolted to an aluminum mount, which can be easily stripped. Our demo vehicle required 35 pound-feet of torque.

Reinstall the belt with the correct routing. Release the tension on the belt to slip it over the pulley the way you did when you removed the belt.

Make a note of the mileage reading. Replace the idler pulley every time you replace the belt. Serpentine belts last about 50,000 to 100,000 miles.

Share your feedback

This article is meant to provide general guidance only. Automotive maintenance, repair, upgrade, and installation may depend on vehicle-specifics such as make and model. Always consult your owner's manual, repair guide for specific information for your particular vehicle and consider a licensed auto-care professional's help as well, particularly for advance repairs.