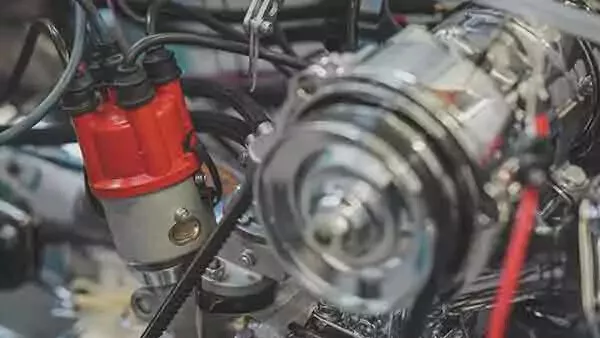

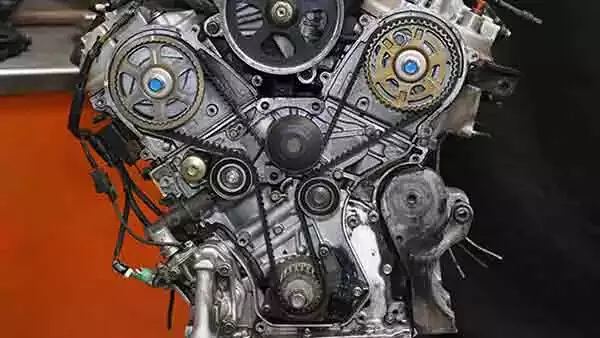

Your vehicle’s accessory drive belt connects the engine crankshaft to accessories such as the AC compressor, alternator, power steering, and water pump. For proper operation, the drive belt must be held tight to each pulley.

The tensioner used on modern serpentine systems is a dynamic device, providing variable tension to adjust for sudden load changes. This prevents the belt from stretching and prematurely wearing out and reduces wear on accessory bearings.

Dynamic belt tensioners are typically powered by a heavy coil spring, rubber elastomer, or hydraulic shock. Most manufacturers recommend replacing the tensioner every 40,000 to 70,000 miles. It’s smart to replace the tensioner when you replace the belt.

Belt tensioners have two failure points: the tensioner device and the pulley bearing. Either can fail, leaving you with a stalled vehicle. The most common symptom of a failing belt tensioner is squealing and groaning. You might also experience a battery warning light, overheating, or burning rubber smell.

Replacing the tensioner on most vehicles is a quick and easy process using basic hand tools.

Tips & Tricks

- It doesn’t make sense to repair belt tensioners. It’s easier and better to replace the tensioner entirely.

- Verify that the replacement tensioner matches the original item and fits your make and model.

- Take a picture of the belt routing before replacing related parts. Photos will be helpful when reinstalling the belt. Not every vehicle has a sticker indicating the belt routing.

- If the tensioner is bad, the belt probably also needs to be replaced.

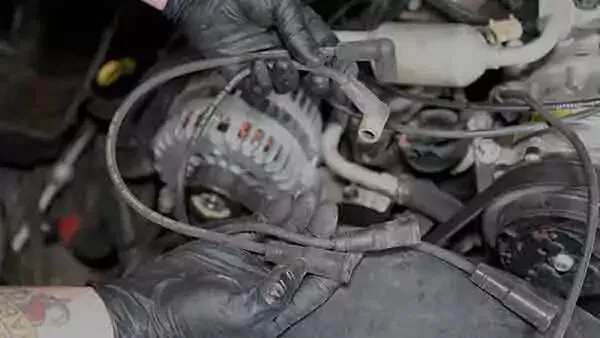

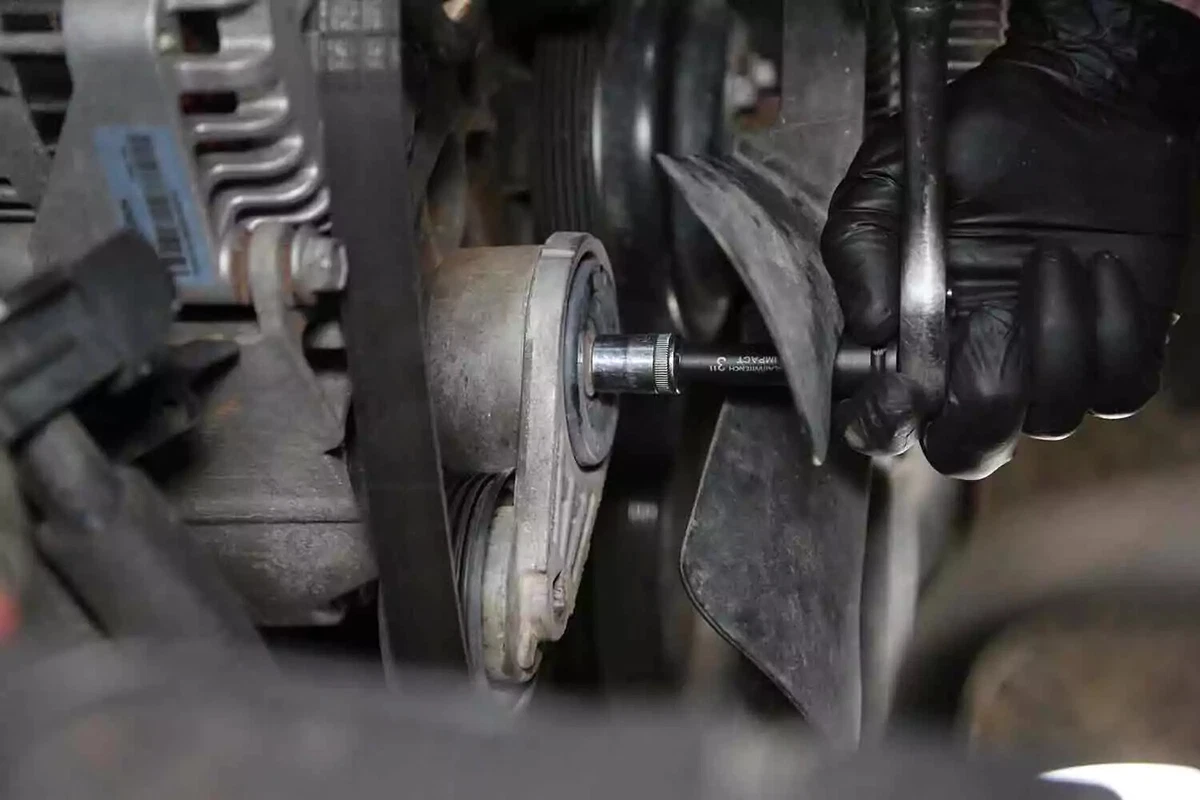

Use a breaker bar or ratchet to release the belt tension. Most tensioners have a 3/8-inch or 1/2-inch square drive for a ratchet or breaker bar. Some require a socket or a Torx bit. Rotate the tensioner arm against the spring to put slack in the belt with one hand while you slip the belt off with the other.

Check your owner’s manual for your vehicle’s recommended method.

You might need to remove some of the radiator shroud to access the tensioner.

While holding the tensioner in the released position, slip the belt off one pulley. If you are replacing the belt, fully remove it.

Release the tensioner.

Unbolt the tensioner from the engine block. A single bolt through the center of the tensioner usually holds it in place.

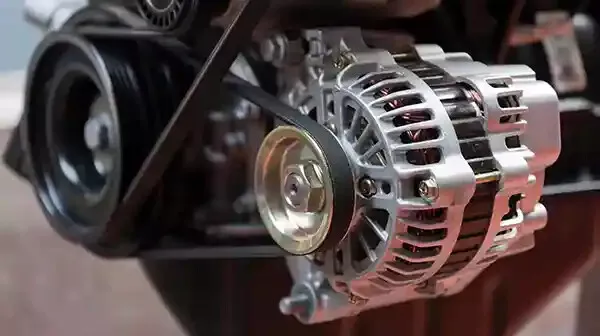

Hold the new and old tensioners next to one another. Verify that they are the same size and have the same mounting and pulley design. Do they have the same number of ribs?

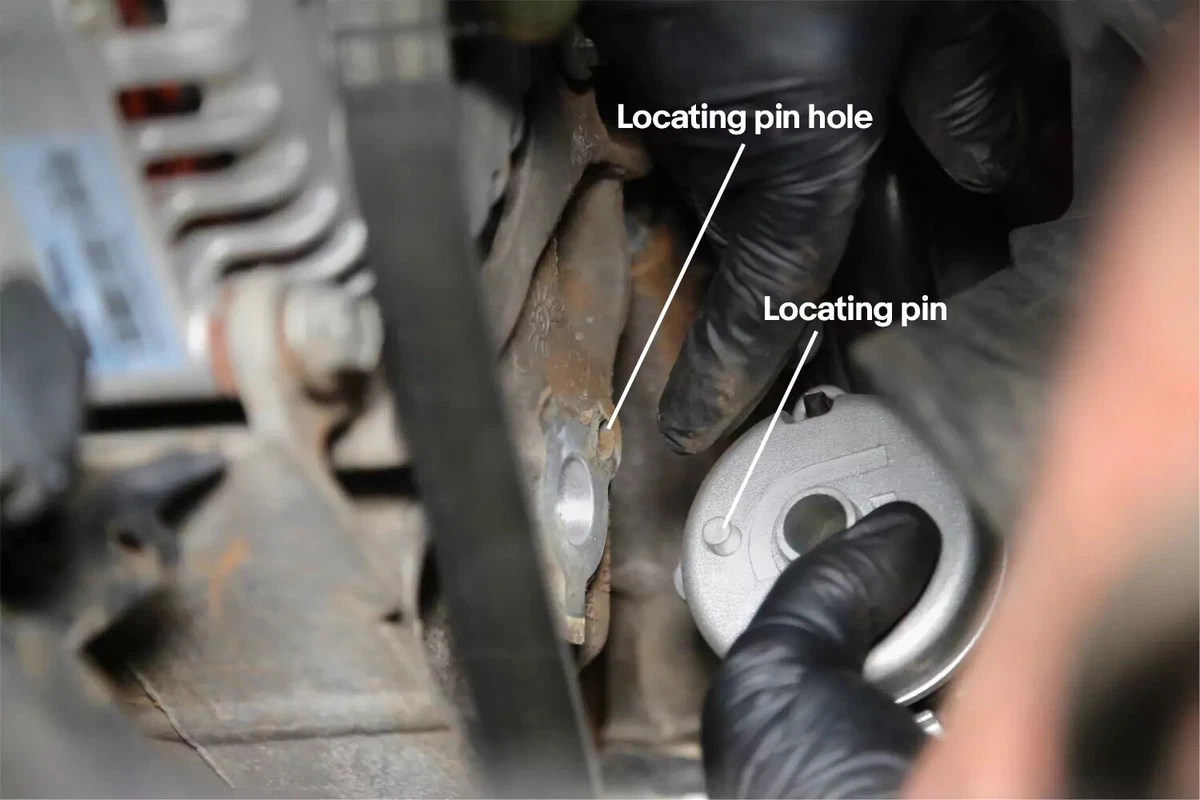

Notice the small pin on the back of this tensioner. That’s what locks the mount in position on the engine.

Verify the mounting features for your engine’s tensioner design. Position the new tensioner on the engine.

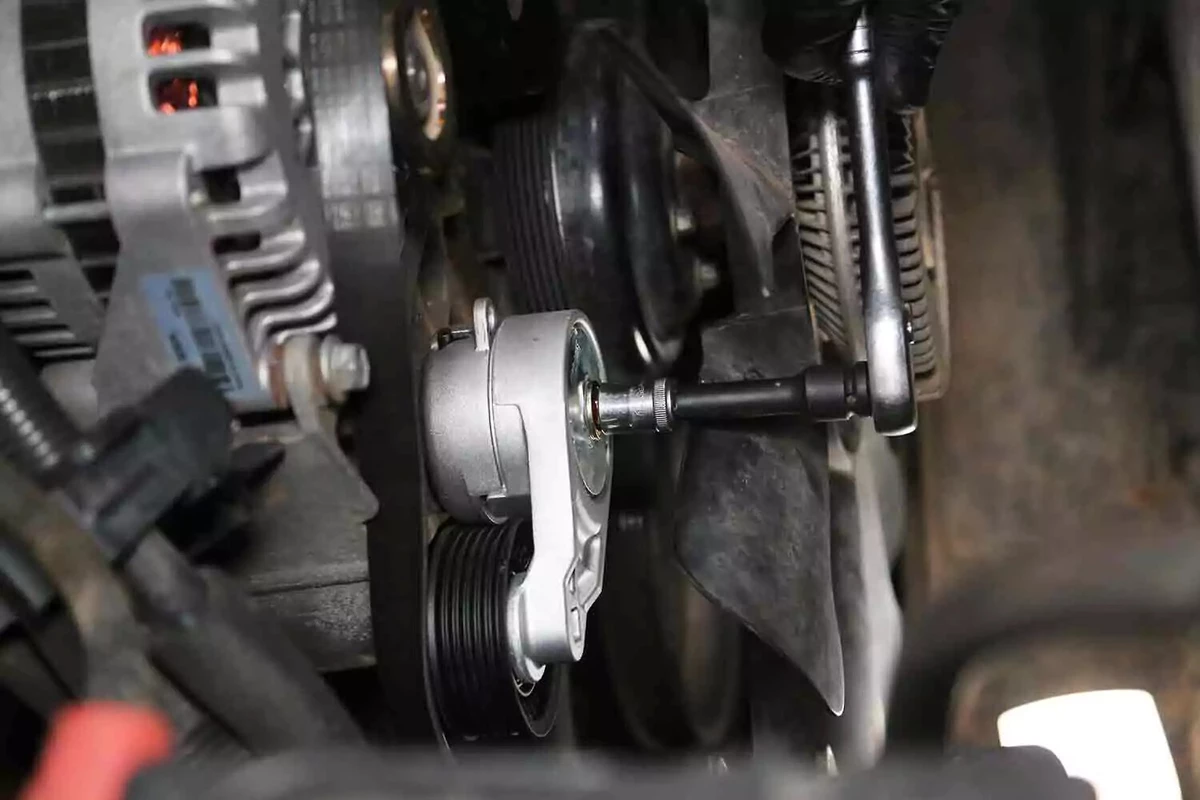

Put the tensioner into place. Thread the fasteners into place. Use new bolts, if available.

Use a socket and ratchet to tighten the bolts to the factory spec.

Verify the torque specs in your service manual. They are usually under 30 pound-feet, so wrench-tight is adequate.

Reinstall the serpentine belt following the original routing. There should be a sticker under the hood detailing the belt routing. If not, consult your repair manual for the correct routing.

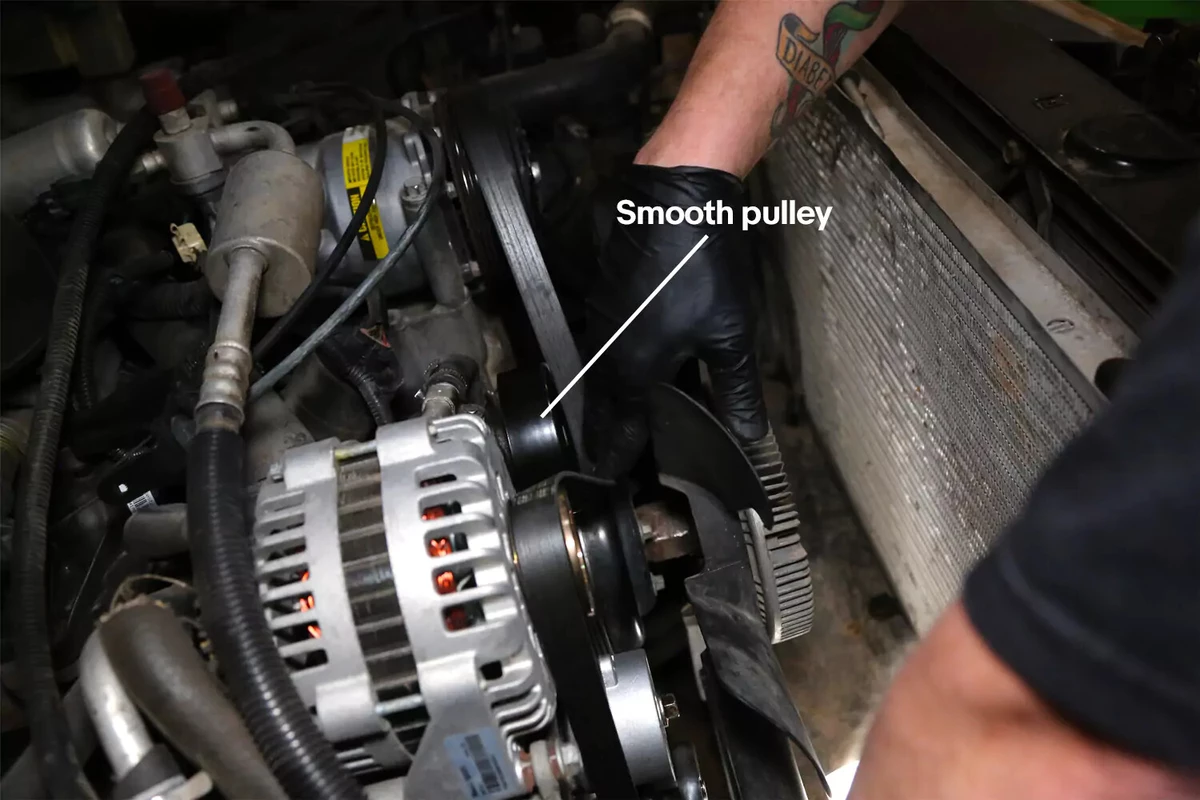

Route the belt over all of the pulleys, including the new one, skipping one smooth idler pulley.

Attach the ratchet or socket to the tensioner and release the tension on the belt. Slip the belt over that last smooth pulley. Release the tensioner, ensuring the ribs are fully engaged on all pulleys. Check the other grooved pulleys to ensure the belt is centered.

It’s important to confirm that the belt is fully on the pulleys. Otherwise, the belt could come off and be damaged.

Share your feedback

This article is meant to provide general guidance only. Automotive maintenance, repair, upgrade, and installation may depend on vehicle-specifics such as make and model. Always consult your owner's manual, repair guide for specific information for your particular vehicle and consider a licensed auto-care professional's help as well, particularly for advance repairs.