The steering system in your vehicle is your only connection to the wheels. You spin the steering gearbox while turning the steering wheel. It converts that input to the wheels. When it wears out, you can introduce play in your steering wheel and erratic handling characteristics.

Rack-and-Pinion Versus Gearbox Steering

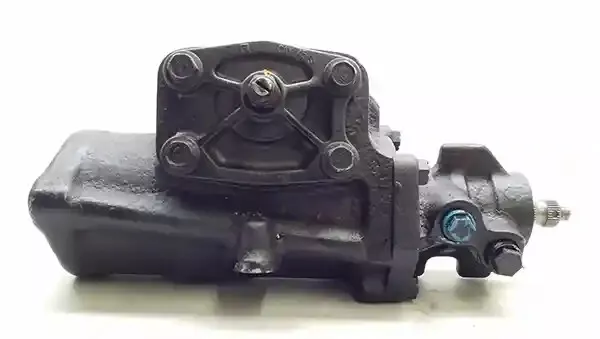

The list of components inside a steering gearbox includes a ball nut rack, sector gear, and worm gear. These items connect the steering wheel to the wheels.

There are two types of steering systems: gearbox and rack-and-pinion. These two systems do the same job in different ways.

Rack-and-pinion steering is the primary design used in modern cars and trucks. Rack-and-pinion steering is simpler than a gearbox because it uses a pinion gear connected to the steering column and a rack gear. The rack gear is a shaft with gear teeth. These simple steering systems are effective but limited in strength. They can be damaged by road debris.

This article focuses on gearboxes, which are found in most cars built before the late 1990s and most larger trucks and SUVs.

What Is a Steering Gearbox?

The sector gear (top gear shaft) is driven by the worm gear (bottom gear).

A steering gearbox is also referred to as a recirculating ball gearbox. Vehicles with this setup are referred to as recirculating ball steering or worm gear drive. This design is robust. Most failures in this type of steering are in the power-assist circuit and the recirculating balls.

The steering input shaft (from the column) is connected to a long gear called a ball nut rack, which is a spiral-grooved gear. A worm gear rides over this rack gear but does not touch it directly. Instead, a series of ball bearings packed in grease separate the two gears. As the rack gear spins, the ball bearings move the worm gear up and down inside the box. This movement is transferred to a sector gear, which operates the steering linkage to the wheels.

Over time, the ball bearings wear down, and the grease thins out, allowing more space between each ball. This produces play in the steering wheel. You can turn the steering wheel, but the wheels don’t turn until the balls have stacked up. Anything more than 1/4-inch of play in the steering wheel is too much. Some believe that 1/8-inch is too loose.

Symptoms of a Failing Steering Box

Grease is crucial for the gearbox to operate and not wear out prematurely.

The most common symptom of a worn-out gearbox is excessive steering wheel play. This is how most gearboxes die: the ball bearings wear out. In severely worn boxes, you may hear grinding or have difficulty turning the wheel. A worn gearbox allows the vehicle to drift on the road without input from the steering wheel. A little play is OK, but severely worn steering boxes are very dangerous.

Failure in your power steering is a related symptom of a failing steering gearbox. The power steering system is a separate entity inside a gearbox. As the input shaft turns, a spool valve opens based on the direction of rotation. The valve allows high-pressure fluid to pass through, pushing on a piston, which pushes on the input shaft and reduces the effort needed to turn the wheels.

This is a complicated system that wears out on its own. When the power assist valve begins to fail, you can experience several issues such as hard steering and self-steering. If the spool valve gets out of adjustment, the steering wheel can turn violently by itself. You can see this in action in our how-to video and article about replacing a steering box - opens in new window or tab..

Can you rebuild a steering gearbox?

Yes. The gearbox portion of a steering gear can be rebuilt at home with a kit. The kits include new ball bearings, gears, gaskets, and seals. You need to clean the gearbox well and use lots of high-pressure lithium grease.

Rebuilding the power assist portion is also doable. However, the kits for that job are harder to find. Also, the casting may be too far gone to rebuild.

Replacing a Steering Gearbox

The hydraulic lines on a power-assist gearbox push high-pressure fluid to reduce the steering effort. These can be difficult to remove due to tight packaging in many vehicles.

Replacing the steering gearbox is an intermediate skill-level DIY job. Expect to spend two to five hours on the repair.

The pitman arm, which is the component that connects the gearbox to the steering linkage, requires around 250 feet-pound of torque. That much torque can be difficult to achieve when lying under the car on the ground.

You need to raise the vehicle safely with the wheel off the ground, so you can’t use ramps. The vehicle must be supported with a jack stand—never a jack alone.

Your vehicle’s steering box is the only way to control the direction of the vehicle. If your vehicle shows signs of a worn-out gearbox, rebuilding or replacing it immediately is the best way to keep you and your passengers safe.

Share your feedback

This article is meant to provide general guidance only. Automotive maintenance, repair, upgrade, and installation may depend on vehicle-specifics such as make and model. Always consult your owner's manual, repair guide for specific information for your particular vehicle and consider a licensed auto-care professional's help as well, particularly for advance repairs.